PDF(766 KB)

PDF(766 KB)

PDF(766 KB)

PDF(766 KB)

PDF(766 KB)

PDF(766 KB)

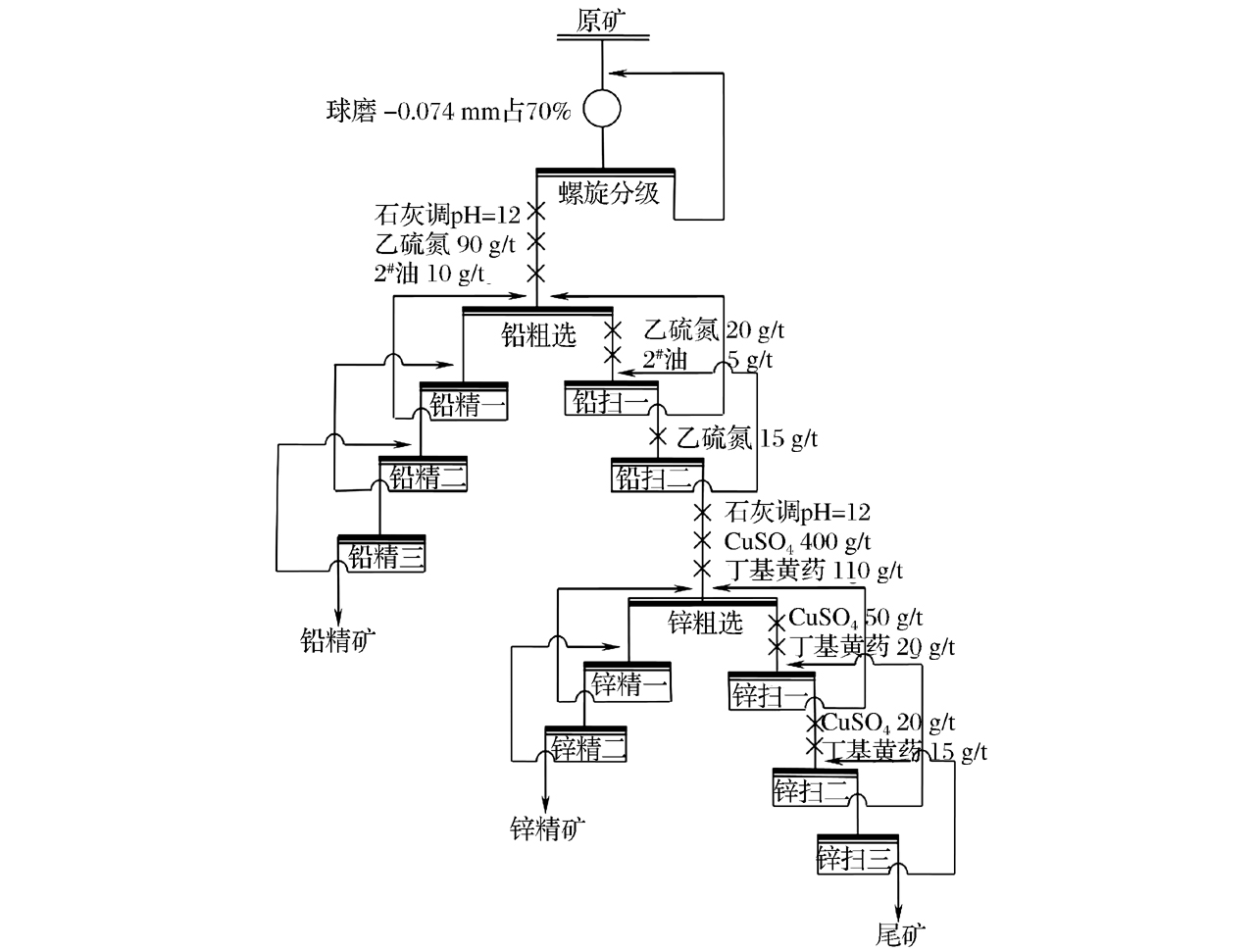

甘肃洛坝铅锌矿选矿流程考察与优化

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Investigation and Optimization of Processing Flowsheet for a Luoba Lead-zinc Mine in Gansu Province

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |