PDF(5530 KB)

PDF(5530 KB)

PDF(5530 KB)

PDF(5530 KB)

PDF(5530 KB)

PDF(5530 KB)

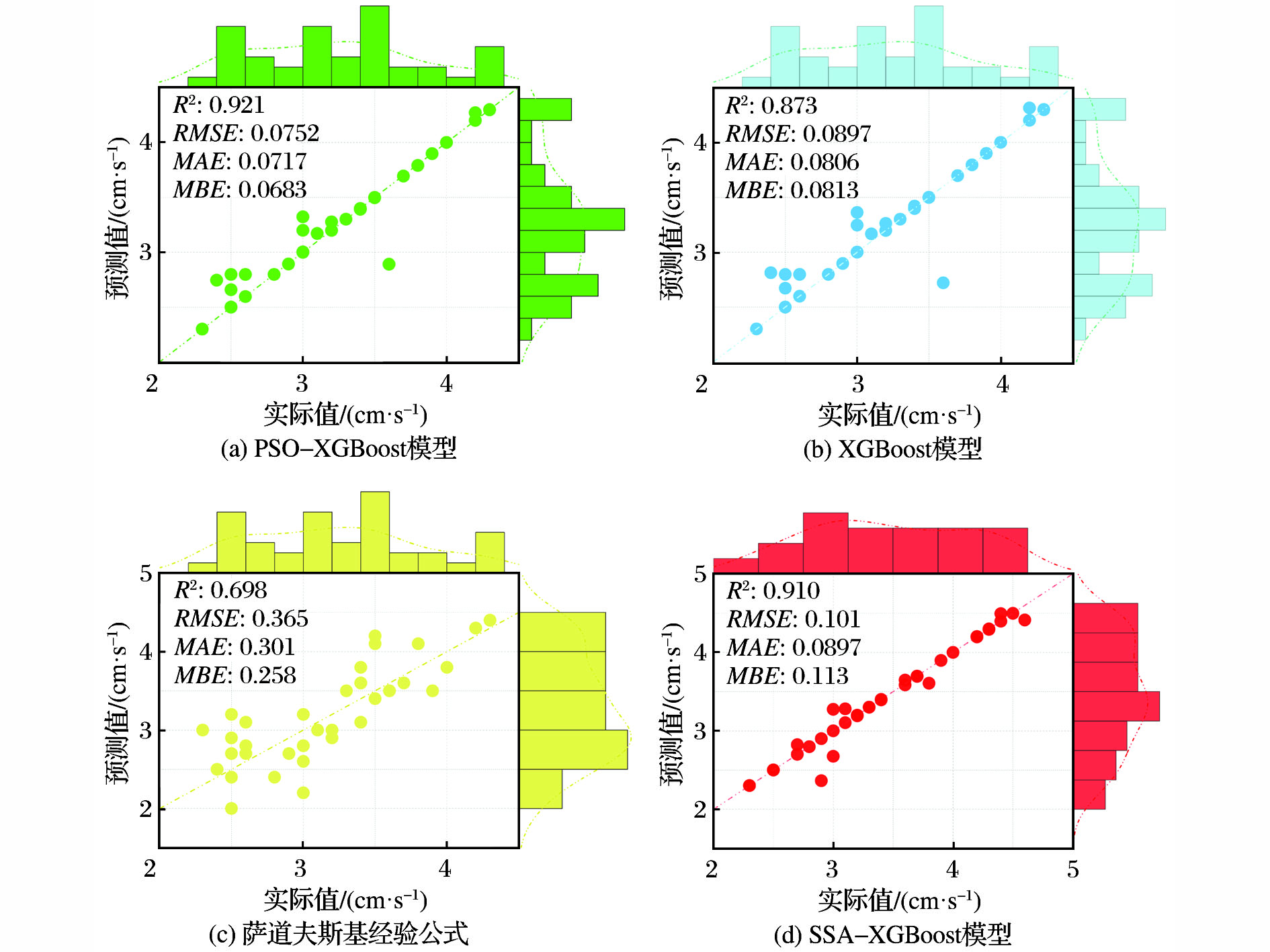

基于PSO-XGBoost的露天矿山PPV预测模型研究

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Research on PPV Prediction Model of Open-pit Mine Based on PSO-XGBoost

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |