PDF(3762 KB)

PDF(3762 KB)

PDF(3762 KB)

PDF(3762 KB)

PDF(3762 KB)

PDF(3762 KB)

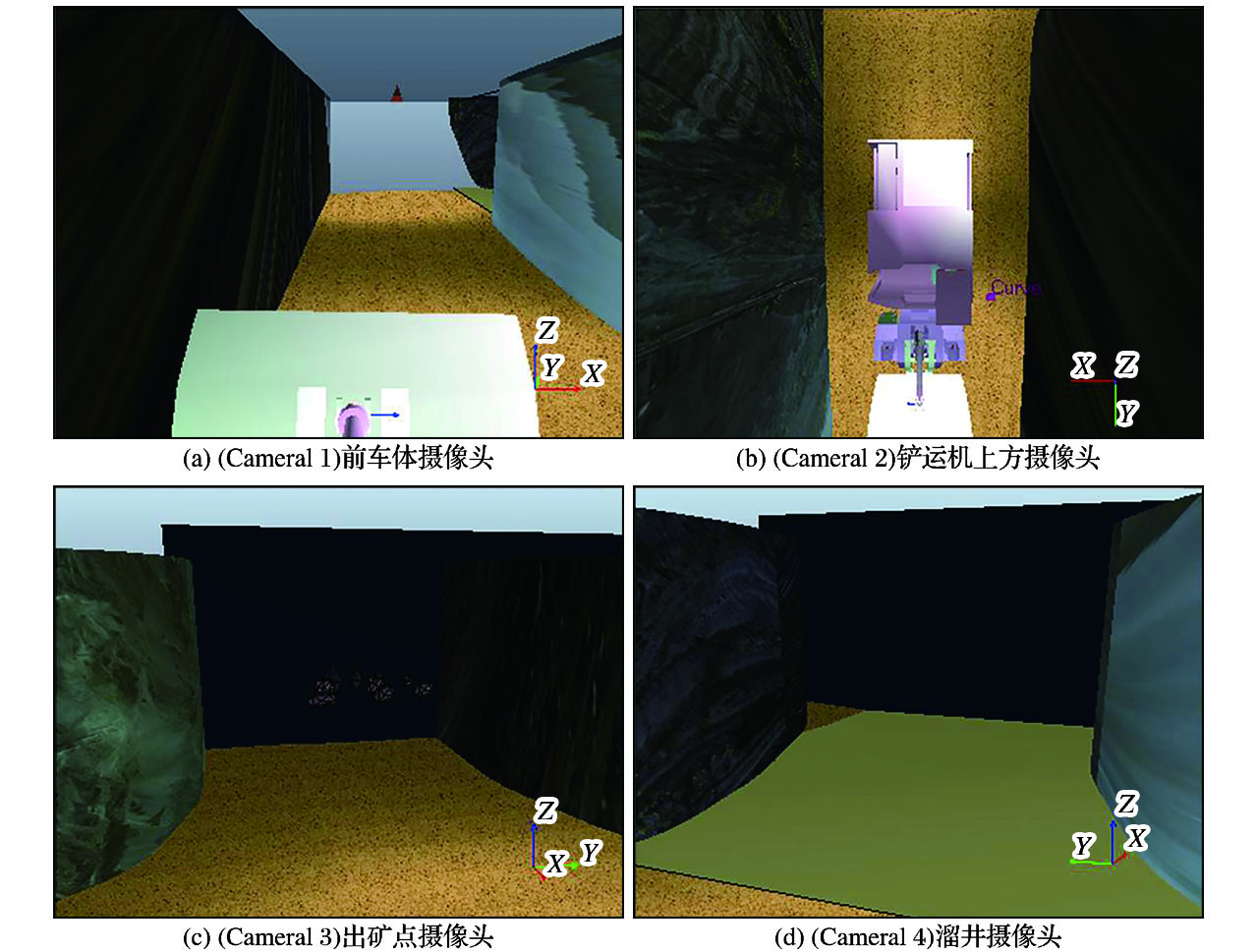

基于V-REP的井下铲运机自主作业仿真试验软件平台研究

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Research on Simulation Software Platform for Underground LHD Operation

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |