随着经济的发展和社会的进步,人们对黄金的需求量日益增加。然而,经过长期的开发利用,金矿资源储量日益减少,涉及地质勘探、采矿、选矿及冶金等行业对黄金采掘生产的高新技术要求日益严苛,突破现有技术瓶颈迫在眉睫(刘科勇,2016;班金彭等,2019;齐剑等,2021)。目前,贫、细、杂等难选冶金矿石的生产回收工艺研发已成为研究热点(杨波等,2020;许晓阳,2020;Salazar-Campoy et al.,2020;吴天骄等,2021;Gui et al.,2021;常征等,2021;Lee et al.,2022)。其中,贵州卡林型金矿为当前难选冶矿石典型代表之一(刘源等,2013;孙忠梅等,2014;崔毅琦等,2014;崔立凤,2018;满露梅,2021;Ng et al.,2022)。

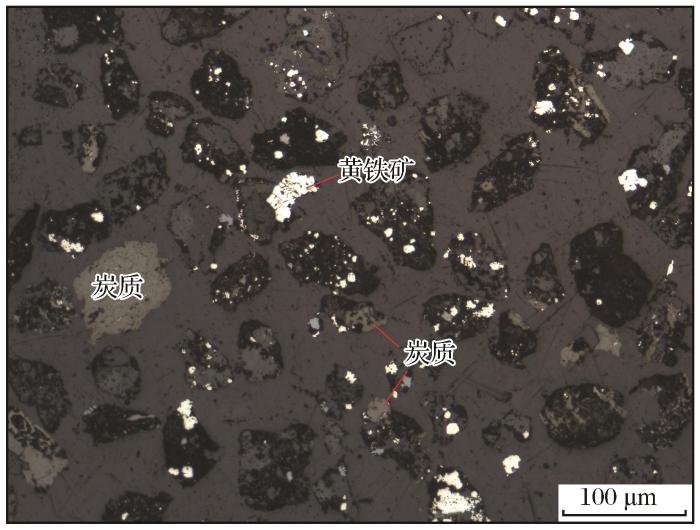

贵州卡林型金矿主要载金矿物为黄铁矿和毒砂,通常呈微细浸染状存在,矿石嵌布粒度微细不均,砷、碳杂质含量较高,属于难选金矿石。在浮选过程中,磨矿细度要求较高,基本达到-0.074 mm占90%以上。然而,磨矿细度较细,导致浮选环境恶化,部分微细颗粒即使已经解离也不能被回收,依旧损失在尾矿中。鉴于此,引进精锐微泡浮选设备,强化回收尾矿中损失微细颗粒显得尤为重要(韦龙明,1996;许涛等,2013;Li et al.,2017;李国等,2019)。

某选厂设计日处理能力为1 800 t/d,共有2个系列,磨浮系统均采用两段闭路磨矿+两粗两精四扫的常规细磨浮选工艺。自2020年11月以来,该浮选系统指标严重恶化,金精矿回收率低,尾矿金损失严重,现有选别工艺难以达到较好的选矿指标,企业经济效益大幅下滑。为了查明尾矿金损失的原因,提高金精矿回收率及降低尾矿品位,开展了工艺矿物学及精锐微泡浮选应用研究。

1 矿石性质

1.1 原矿多元素、金物相及矿物组成分析

表1 原矿多元素分析结果

Table 1

| 化学成分 | 含量 | 化学成分 | 含量 |

|---|---|---|---|

| Au | 3.98 | Pb | 0.01 |

| Ag | <0.01 | Zn | 0.01 |

| TS | 5.80 | CaO | 7.49 |

| S2- | 5.12 | MgO | 2.63 |

| As | 0.41 | Al2O3 | 4.69 |

| C | 6.03 | SiO2 | 37.03 |

| C有机 | 1.53 | TiO2 | 0.82 |

| Fe | 8.22 | Hg | 0.001 |

表2 原矿金物相分析结果

Table 2

| 相别 | 含量/(×10-6) | 占比/% |

|---|---|---|

| 合计 | 3.990 | 100.00 |

| 裸露金 | 0.165 | 4.14 |

| 碳酸盐和氧化物包裹金 | 0.058 | 1.44 |

| 硫化物和碳质包裹金 | 3.530 | 88.53 |

| 硅酸盐及其他包裹金 | 0.235 | 5.89 |

表3 原矿矿物组成及含量分析结果

Table 3

| 矿物名称 | 含量 | 矿物名称 | 含量 |

|---|---|---|---|

| 黄铁矿 | 9.63 | 铁白云石 | 31.05 |

| 毒砂 | 0.34 | 白云石 | 5.70 |

| 磁黄铁矿 | 0.01 | 方解石 | 9.19 |

| 黄铜矿 | 0.01 | 菱铁矿 | 0.19 |

| 闪锌矿 | 0.01 | 石英 | 30.78 |

| 方铅矿 | <0.01 | 绢云母 | 9.34 |

| 褐铁矿 | 0.08 | 绿泥石 | 0.14 |

| 铁矾 | 0.02 | 锐钛矿 | 1.52 |

| 重晶石 | 0.05 | 有机碳 | 1.34 |

| 磷灰石 | 0.26 | 其他矿物 | 0.34 |

1.2 尾矿中金损失分析

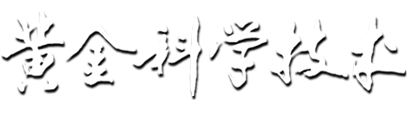

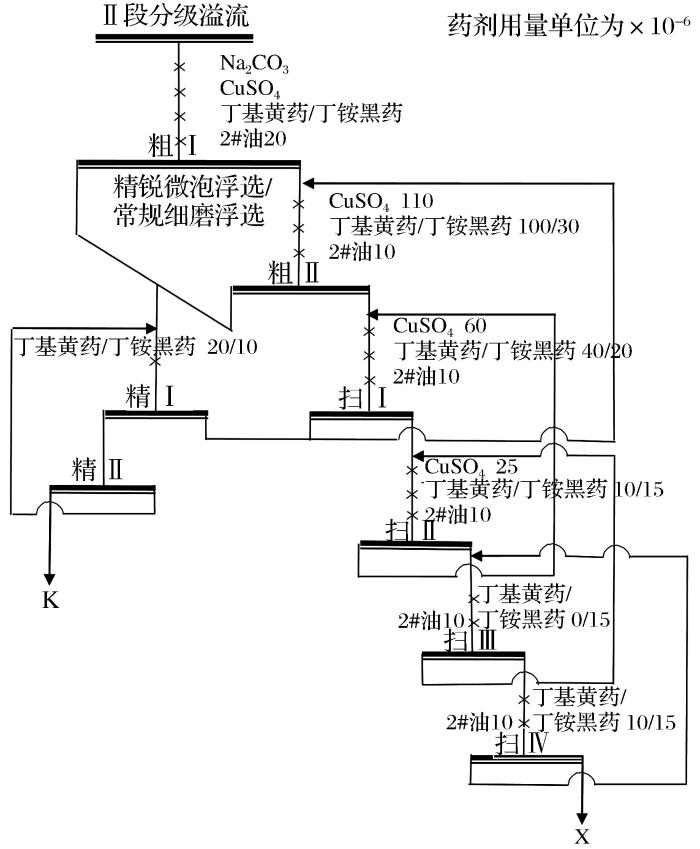

采用现场两粗两精四扫浮选流程生产时,金回收率仅为80.54%,尾矿金品位为0.97×10-6,尾矿金损失严重,选别流程如图1所示。为了查明尾矿金损失的原因,开展二段磨矿分级溢流及浮选尾矿硫化物解离连生情况及粒度分析。

图1

当磨矿细度为-75 μm占比为89.79%时,二段分级溢流尾矿中硫化物单体解离度为78.27%,富连生体为10.29%,贫连生体为11.44%。未解离的硫化物主要与硅酸盐矿物连生,主要分布在20~75 μm粒级中。在-10 μm粒级中硫化物以解离单体和贫连生体为主,占比分别为13.11%和4.65%,该粒级金不易回收。由二段分级溢流尾矿粒度筛析可知:-38 μm粒级含量为69.04%;-25 μm粒级含量为62.79%,该粒级金品位高,金属分布率为35.10%;-10 μm 粒级含量高达43.90%,该粒级金品位略低,金属分布率为34.06%。二段分级溢流尾矿硫化物解离情况较好,-25 μm细粒级金品位略低但含量占比较高,结果见表4和表5。

表4 二段磨矿分级溢流尾矿中硫化物的粒度—解离连生情况

Table 4

| 解离情况/% | 含量/% | 硫化物连生情况/% | 各粒度占比/% | |||||

|---|---|---|---|---|---|---|---|---|

| 与氧化物及碳酸盐 | 与硅酸盐及碳质 | 0~10 μm | 10~20 μm | 20~38 μm | 38~75 μm | 75~150 μm | ||

| 合计 | 100.00 | 3.04 | 18.69 | 18.06 | 29.14 | 35.93 | 15.89 | 0.98 |

| x=100 | 78.27 | - | - | 13.11 | 22.62 | 29.39 | 12.47 | 0.68 |

| 80≤x<100 | 5.22 | 0.64 | 4.58 | 0.02 | 0.34 | 2.34 | 2.32 | 0.20 |

| 50≤x<80 | 5.07 | 0.69 | 4.38 | 0.28 | 2.14 | 1.91 | 0.64 | 0.10 |

| x<50 | 11.44 | 1.71 | 9.73 | 4.65 | 4.04 | 2.29 | 0.46 | 0.00 |

表5 二段磨矿分级溢流尾矿粒度组成及金金属分布

Table 5

| 粒级/mm | 产率/% | 金品位 /(×10-6) | 金金属分布率/% | |

|---|---|---|---|---|

| 个别 | 负累积 | |||

| 合计 | 100.00 | - | 4.02 | 100.00 |

| +0.074 | 10.21 | 100.00 | 2.39 | 6.07 |

| -0.074+0.045 | 13.76 | 89.79 | 3.01 | 10.29 |

| -0.045+0.038 | 6.99 | 76.04 | 4.04 | 7.02 |

| -0.038+0.025 | 6.25 | 69.04 | 4.80 | 7.46 |

| -0.025+0.010 | 18.89 | 62.79 | 7.47 | 35.10 |

| -0.010 | 43.90 | 43.90 | 3.12 | 34.06 |

表6 浮选尾矿中硫化物的粒度—解离连生情况

Table 6

| 解离情况/% | 含量/% | 硫化物连生情况/% | 各粒度占比/% | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 与氧化物 | 与碳酸盐 | 与硅酸盐 | 0~10 μm | 10~20 μm | 20~38 μm | 38~75 μm | 75~150 μm | ||

| 合计 | 100.00 | 6.16 | 12.48 | 59.46 | 42.79 | 35.31 | 17.63 | 3.89 | 0.38 |

| x=100 | 21.90 | - | - | - | 12.81 | 6.42 | 1.73 | 0.94 | 0.00 |

| 80≤x<100 | 7.61 | 3.22 | 0.36 | 4.03 | 1.02 | 3.56 | 2.57 | 0.46 | 0.00 |

| 50≤x<80 | 9.79 | 2.54 | 0.61 | 6.64 | 2.02 | 3.48 | 3.04 | 0.87 | 0.38 |

| x<50 | 60.70 | 0.40 | 11.51 | 48.79 | 26.94 | 21.85 | 10.29 | 1.62 | 0.00 |

表7 浮选尾矿粒度组成及金金属分布

Table 7

| 粒级/mm | 个别产率 /% | 负累积产率 /% | 金品位 /(×10-6) | 金金属分布率 /% |

|---|---|---|---|---|

| 合计 | 100.00 | - | 1.28 | 100.00 |

| +0.074 | 11.81 | 100.00 | 1.66 | 15.26 |

| -0.074+0.045 | 14.86 | 88.19 | 1.87 | 21.63 |

| -0.045+0.038 | 5.60 | 73.33 | 1.78 | 7.76 |

| -0.038+0.025 | 7.03 | 67.73 | 1.65 | 9.03 |

| -0.025+0.010 | 19.58 | 60.70 | 1.51 | 22.95 |

| -0.010 | 41.12 | 41.12 | 0.73 | 23.37 |

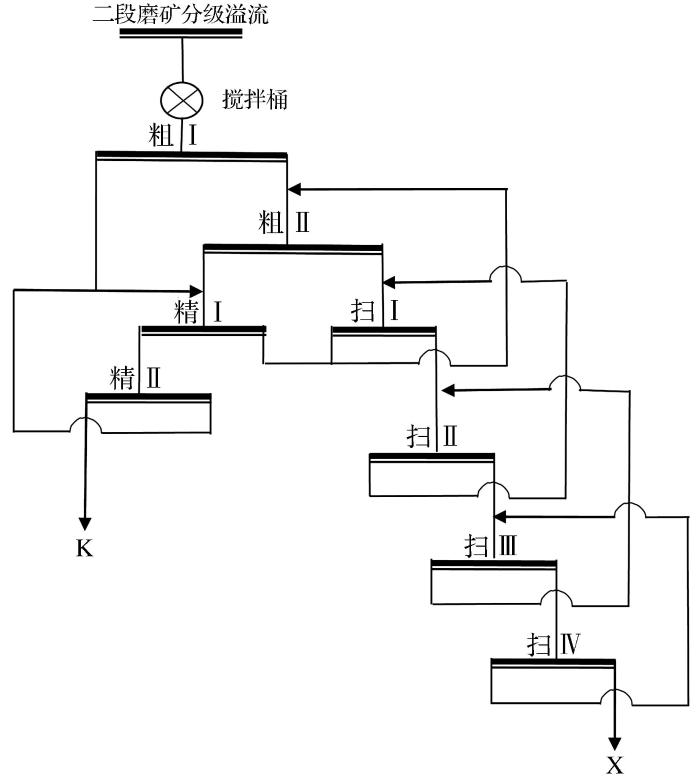

图2

2 精锐微泡浮选机应用研究

基于前期研究结果,为了回收常规浮选尾矿中损失的金,强化微细粒级矿物浮选,增加选别作业回收率,降低尾矿品位,考虑进行现场生产工艺优化。结合现场生产尾矿金损失现状,引进精锐微泡浮选技术及设备,分别应用于粗选Ⅰ作业及扫选Ⅳ尾矿再选作业,基于此开展工业试验对比研究。

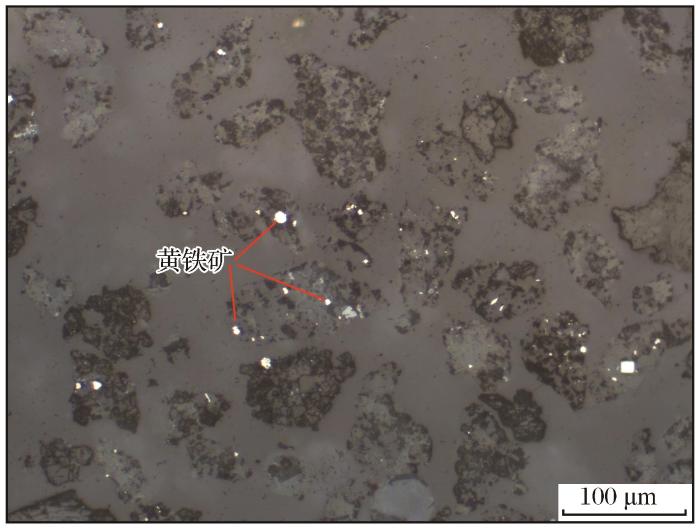

2.1 精锐微泡浮选机结构与原理

图3

图3

精锐微泡浮选机设备结构及原理示意图

Fig.3

Schematic diagram of structure and principle JRF micro-bubble flotation machine

2.2 粗选Ⅰ作业工业试验对比

图4

图4

粗选Ⅰ作业工业试验对比流程

(精锐微泡浮选与常规浮选)

Fig.4

Comparison process of the rough selection Ⅰoperation

(JRF micro-bubble flotation with

conventional flotation)

表8 浮选设备型号及规格

Table 8

| 作业名称 | 设备型号 | 数量/台 | 容积/m3 |

|---|---|---|---|

| 粗选 | BF-10 | 7 | 10 |

| 扫选 | BF-10 | 18 | 10 |

| 精选 | BF-4 | 5 | 4 |

| 微泡浮选 | JRF3217/4S | 1 | 10 |

在粗选Ⅰ作业中分别使用精锐微泡浮选机和常规浮选设备进行选别,获得各项生产指标。结果表明:精锐微泡浮选尾矿金品位为1.13×10-6,精矿回收率为80.89%,常规浮选尾矿金品位为1.07×10-6,精矿回收率约为79.33%,二者生产指标相当,试验结果见表9。

表9 粗选Ⅰ作业中精锐微泡浮选与常规浮选的工业试验结果对比

Table 9

| 项目 | 金品位/(×10-6) | 产率/% | 金回收率/% | ||

|---|---|---|---|---|---|

| 原矿 | 精矿 | 尾矿 | |||

| 精锐微泡浮选 | 4.71 | 18.86 | 1.13 | 20.20 | 80.89 |

| 常规细磨浮选 | 4.26 | 19.24 | 1.07 | 17.56 | 79.33 |

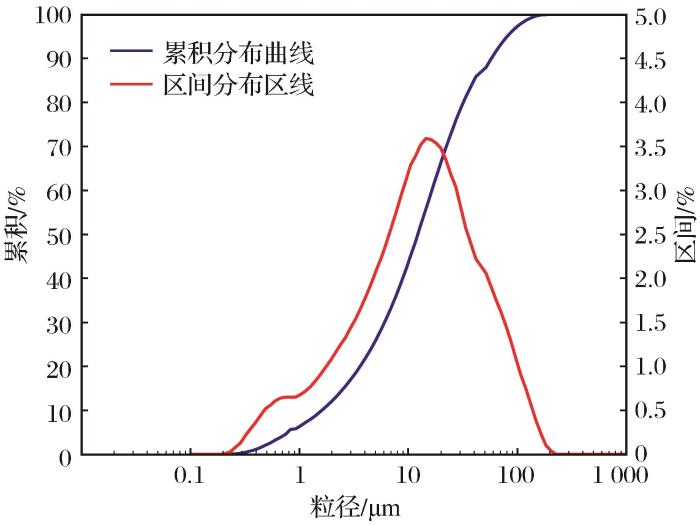

图5

图5

精锐微泡浮选粗选Ⅰ精矿产品粒度分布曲线

Fig.5

Particle size distribution curves of the concentrate products from rough selection Ⅰby JRF micro-bubble flotation

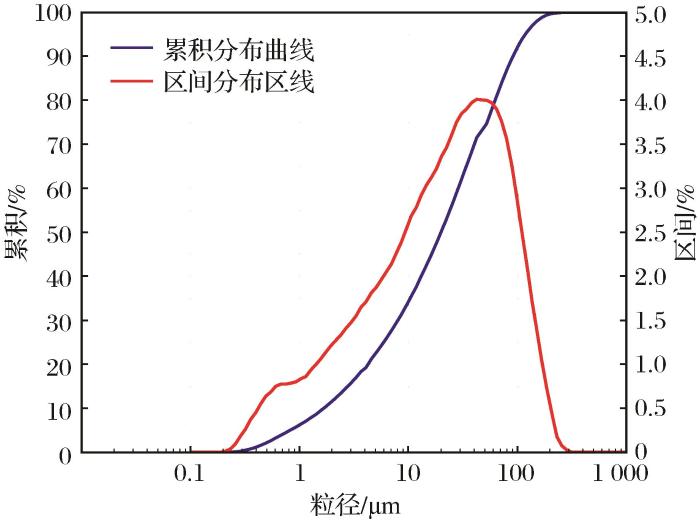

图6

图6

常规浮选粗选Ⅰ精矿产品粒度分布曲线

Fig.6

Particle size distribution curves of the concentrate products from rough selection Ⅰby conventional flotation

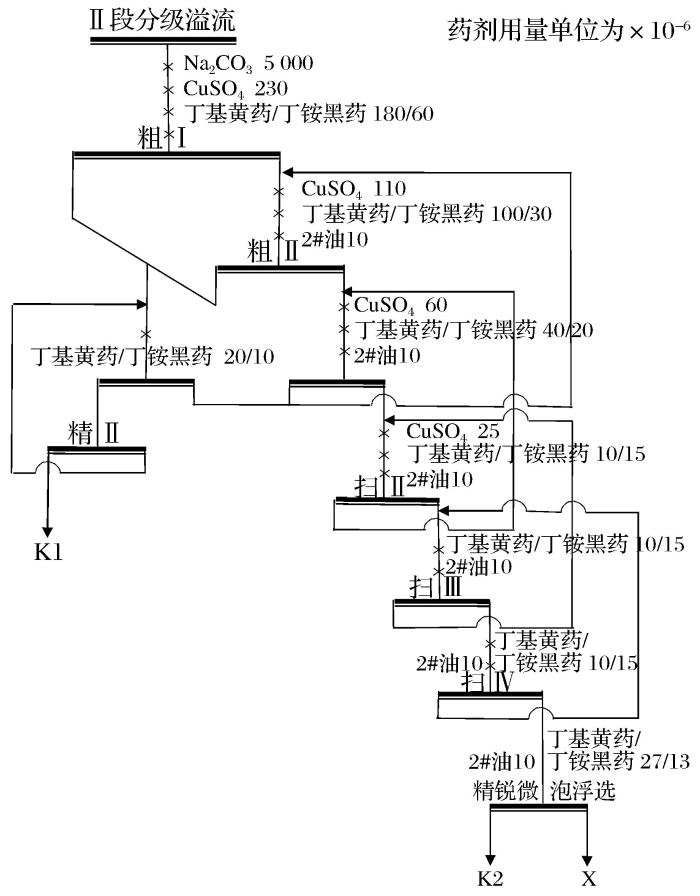

2.3 扫选Ⅳ尾矿再选工业试验对比

为了强化回收常规浮选尾矿中损失的金,捕收尾矿中微细粒级矿物,应用精锐微泡浮选设备对常规浮选尾矿进行再选工业试验,并与常规浮选进行对比,试验流程如图7所示。

图7

图7

扫Ⅳ尾矿再选工业试验对比流程

(精锐微泡浮选与常规浮选)

Fig.7

Comparison process of the scavenging Ⅳ tailing reselection

(JRF micro-bubble flotation with conventional flotation)

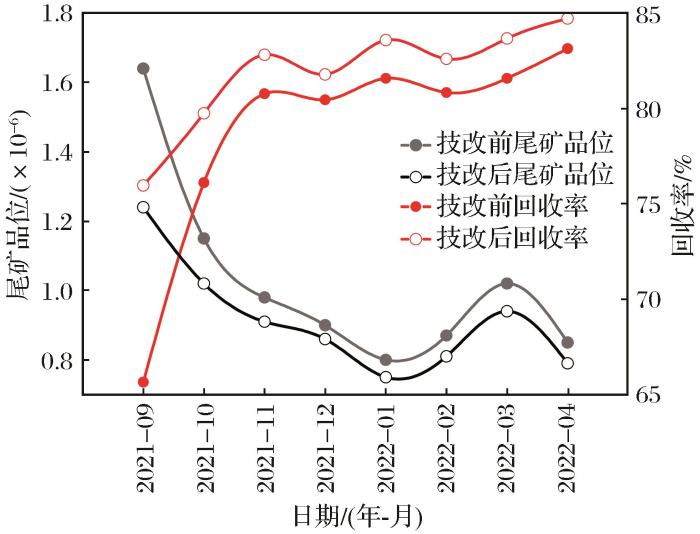

2021年8月完成现场改造及调试后,选矿回收率有所提升,浮选尾矿金损失显著下降。2021年9~12月综合浮选金累计回收率为79.72%,尾矿金品位为1.03×10-6,相比技改优化前金回收率提高了1.5个百分点,尾矿金品位降低了0.06×10-6。截至2022年4月的生产数据表明,入选原矿金品位为3.5×10-6~4.5×10-6,精矿产率约为20%,常规浮选精矿金品位随原矿金品位变化有所波动,金累计回收率仅为80.54%,尾矿金品位为0.97×10-6。精锐微泡浮选金累计回收率为82.39%,尾矿金品位为0.88×10-6。工艺优化后,金回收率提高了1.85个百分点,尾矿金品位降低了0.09×10-6,精锐浮选精矿金品位约为3×10-6,由于精矿金品位较低,将其单独堆存用于后期生产配矿时加入加压氧化工序,整体金回收效果较好,指标对比如图8所示。

图8

图8

技改前后工业试验指标对比

Fig.8

Comparison of industrial test index before and after technical transformation

2.4 精锐微泡浮选精矿产品分析

表10 精锐微泡浮选精矿中硫化物的粒度—解离连生情况

Table 10

| 解离情况/% | 含量/% | 硫化物连生情况/% | 各粒度占比/% | |||||

|---|---|---|---|---|---|---|---|---|

| 与氧化物和碳酸盐 | 与硅酸盐 | 0~10 μm | 10~20 μm | 20~38 μm | 38~75 μm | 75~150 μm | ||

| 合计 | 100.00 | 10.75 | 65.07 | 33.53 | 32.71 | 23.32 | 9.66 | 0.78 |

| x=100 | 24.19 | - | - | 13.76 | 7.06 | 1.98 | 1.24 | 0.15 |

| 80≤x<100 | 5.41 | 1.20 | 4.22 | 0.07 | 0.73 | 1.97 | 2.50 | 0.14 |

| 50≤x<80 | 7.23 | 1.29 | 5.94 | 0.62 | 2.10 | 3.00 | 1.25 | 0.26 |

| x<50 | 63.17 | 8.26 | 54.91 | 19.08 | 22.82 | 16.37 | 4.67 | 0.23 |

表11 精锐微泡浮选精矿粒度组成及金属分布

Table 11

| 粒级/mm | 个别产率 /% | 负累积产率 /% | 金品位 /(×10-6) | 金金属分布率 /% |

|---|---|---|---|---|

| 合计 | 100.00 | - | 4.48 | 100.00 |

| +0.106 | 3.35 | 100.00 | 1.85 | 1.38 |

| -0.106+0.074 | 22.93 | 96.65 | 3.64 | 18.63 |

| -0.074+0.045 | 21.38 | 73.72 | 4.67 | 22.29 |

| -0.045+0.038 | 8.43 | 52.34 | 4.71 | 8.86 |

| -0.038+0.025 | 5.22 | 43.91 | 4.78 | 5.57 |

| -0.025 | 38.69 | 38.69 | 5.01 | 43.26 |

图9

图9

精锐微泡浮选精矿中的微细贫连生体黄铁矿

Fig.9

Fine particles coenobium of pyrite in JRF micro-bubble flotation concentrate

2.5 精锐微泡浮选机选别微细颗粒机理分析

为了解精锐微泡浮选机对细粒回收效果较优的原因,对其机理进行分析。首先,矿浆高压给矿进入喷嘴后形成高速射流,矿浆喷射时产生负压吸入空气,在流体高度紊动剪切作用下,吸入的空气在下冲管狭小空间内产生大量微小气泡,较短时间内即可完成矿化过程。其次,精锐微泡浮选机产生的气泡直径为0.3 mm,而常规浮选机产生的气泡直径大于1 mm,在保持相同气容量的前提下,精锐微泡浮选机产生的气泡数量更多,气泡表面积增大,使得气泡与微细颗粒矿物间的碰撞和吸附均远高于常规浮选机(陈晓东,2021)。最后,虽然精锐微泡浮选机没有搅拌装置,但其通过喷嘴给矿形成高速射流时,也增大了矿浆流速,形成强烈湍流环境,有利于微细颗粒浮选(曹亦俊等,2017)。

3 结论

(1)常规浮选尾矿中损失的金主要以硫化物-38 μm粒级的贫连生体形式损失,占比高达60.70%,此外还有少量解离单体及少量富连生体由于粒度较细没有完全回收也损失在尾矿中。

(2)粗选Ⅰ作业中使用精锐微泡浮选替代常规浮选设备,精锐微泡浮选精矿产品-38 μm粒级占比高达81.52%,而常规浮选精矿产品中-38 μm粒级占比仅为65.45%。精锐微泡强化了-38 μm细粒级矿物的捕收。

(3)对扫Ⅳ尾矿进行再选时,精锐微泡浮选能强化捕收常规细磨浮选扫Ⅳ尾矿中粒度在-38 μm粒级的硫化物贫连生体及少量-20 μm粒级的硫化物解离单体。技改后,选矿回收率有所提升,浮选尾矿金损失显著下降。金累计回收率为82.39%,金回收率提高了1.85%,尾矿金品位降低了0.09×10-6,整体金回收效果较好,浮选指标显著提升,提升了企业经济效益。

(4)分析认为精锐微泡浮选机的优势在于产生大量微小气泡,增加气泡与微细颗粒之间的碰撞和吸附,同时高压射流喷射时产生湍流环境,有利于微细颗粒矿物浮选。

http://www.goldsci.ac.cn/article/2023/1005-2518/1005-2518-2023-31-4-689.shtml

参考文献

Challenges and countermeasures for water kicks in tunnel drilling at Shuiyindong gold mine in southwest Guizhou

[J].

The micro-turbulence intensification on the fine minerals flotation

[J].

Experimental research on the mineral processing of refractory microfine disseminated arsenic and carbonaceous gold ore from Qinghai

[J].

Principle and practice of enhanced flotation performance of fine particles by JRF micro-bubble flotation machine

[J].

Flotation machine

[J].

Experimental study on mineral processing of fine-grained and disseminated refractory carbon gold ore from Shuiyindong of Guizhou

[J].

Research on the status of pretreatment techniques for carlin-type gold deposits

[J].

The mechanism of ultrasound oxidation effect on the pyrite for refractory gold ore pretreatment

[J].

Enhanced gold recovery from alkaline pressure oxidized refractory gold ore after its mechanical activation followed by thiosulfate leaching

[J].

Occurrence of gold in Shuiyindong gold deposit,Guizhou

[J].

Mineralogy and geochemistry characteristics and genetic implications for stratabound carlin-type gold deposits in southwest Guizhou,China

[J].

Problems and suggestions existing in gold mine development in China

[J].

Present situation of research into carlin-type gold deposits in China

[J].

Research and exploration on the combined technology of beneficiation and metallurgy for complex carlin type gold deposits

[J].

Characterization of preg-robbing carbonaceous minerals from the Shuiyindong carlin-type gold deposit via spectroscopic techniques

[J].

Development trend and policy suggestions of China’s gold industry

[J].

Comparative study of gold extraction from refractory pyritic ores through conventional leaching and simultaneous pressure leaching/oxidation

[J].

Study on flotation technology on carlin types gold ore in Guizhou

[J].

General characters of gold mineral in carlin-type gold deposit,China

[J].

Study on gold extraction from a carbon-bearing fine-grained refractory gold ore by flotation process

[J].

Study on modes of occurrence of gold for Shuiyindong gold bearing pyrite in Guizhou Province

[J].

Research on extracting gold from refractory gold ore by POX-cyanidation technique

[J].

Study on the gold recovery from flotation tailings of a refractory gold ores in Gansu Province by a process combining mineral processing and metallurgy

[J].

黔西南水银洞金矿涌水坑道钻探难点与对策

[J].

微细粒浮选的微观湍流强化

[J].

青海某含砷含碳微细浸染型难处理金矿石选矿试验研究

[J].

精锐微泡浮选机强化微细粒浮选的机理与实践

[J].

浮选机

[J].

贵州水银洞含炭细粒浸染型难选冶金矿石选矿试验研究

[J].

卡林型金矿预处理技术研究现状

[J].

贵州水银洞金矿金的赋存状态

[J].

我国金矿开发存在的问题及建议

[J].

我国卡林型金矿研究现状

[J].

复杂卡林型金矿选冶联合工艺的研究与探索

[J].

我国黄金行业发展趋势及政策建议

[J].

贵州某卡林型金矿浮选工艺研究

[J].

中国卡林型金矿床金矿物的一般特征

[J].

某含碳微细粒难处理金矿浮选提金工艺研究

[J].

贵州水银洞含金黄铁矿中金的赋存形式探讨

[J].

难处理金矿石加压氧化——氰化提金技术研究

[J].

选冶联合提高甘肃某难浸金矿浮选尾矿金回收率的试验研究

[J].

甘公网安备 62010202000672号

甘公网安备 62010202000672号