矿山选厂生产的尾砂料浆经沉降过程提高浓度后用于井下充填是矿山充填料浆制备的主要手段,然而,当尾砂颗粒较细时,尾砂自然沉降速率较慢,往往出现严重的溢流跑浑,因而难以实现有效的浓缩[1,2,3,4]。采用添加絮凝剂的方式,可加快尾砂沉降并减少溢流跑浑,是解决细尾砂沉降跑浑和高效浓缩的有效手段[5,6,7,8]。但是,添加絮凝剂后的尾砂浆底流浓度较低,往往难以满足矿山高浓度充填的目的,国内外对此采取的技术手段和措施主要是对絮凝沉降过程进行干扰,最大程度地减少或排除沉降絮团中的“包裹水”以达到提高絮凝沉降浓度的目的,深锥浓密机中的旋转耙架即是这一技术手段的典型应用[9,10,11,12,13,14,15,16]。然而,絮团的动态沉降过程与其吸水能力、尾砂颗粒的比表面积、干扰源特征等因素息息相关,沉降结果是多因素共同作用的结果,目前对其沉降规律研究不足。因此,开展动态絮凝沉降规律研究显得十分必要,是实现细尾砂浆高浓度充填的必由路径[17,18,19,20]。

1 试验材料

对某矿山充填用细尾砂现场取样。在实验室内采用比重瓶法测得尾砂相对密度为3.04,采用容砂法测得尾砂堆积密度为1.40 g/cm3;采用烘干法测得尾砂天然含水率为0.58%;经XRD谱图分析得知,尾砂中以珍珠云母和皂石为主;粒度测试采用马尔文激光粒度测试仪,测得尾砂比表面积为0.890 m2/g,0.037 mm粒级以下尾砂颗粒占比为51.41%,0.075 mm粒级以下尾砂颗粒占比为63.58%。试验采用的聚丙烯酰胺(APAM)阴离子型有机高分子絮凝剂,为国产某知名品牌产品,试验样料为白色粉末,无毒、无味、无腐蚀性,相对分子量为8×106级。

2 低频动态絮凝沉降试验

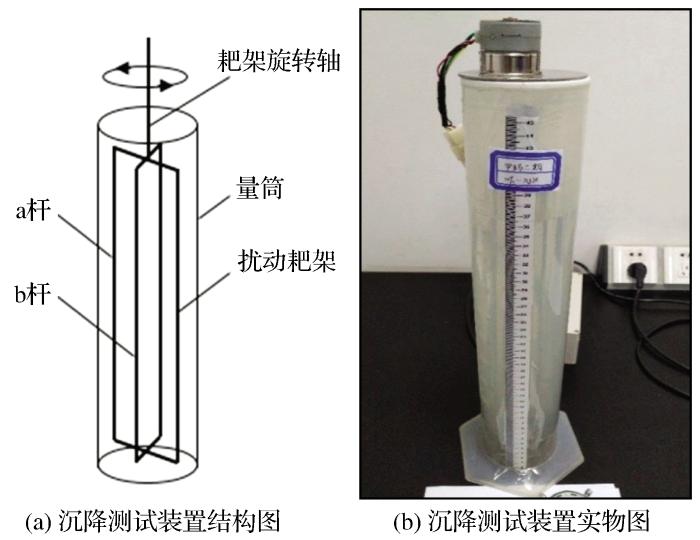

图1

试验方案设计:试验设置对照组和测试组,对照组采用量筒法开展静态絮凝沉降,测试组采用带扰动耙架的同规格量筒开展动态絮凝沉降试验,扰动耙架的扰动旋转速率经过多次反复预试验,得到综合效率最优转速为1/6 r/min,故设计试验转速为1/6 r/min,2组试验开展24 h后测底流浓度。试验组与对照组其他试验条件完全相同,具体试验指标如下:絮凝剂为某品牌70100型,絮凝剂用量分别为10 g/t和15 g/t,料浆质量浓度分别为10% 和12%。

3 结果分析

3.1 试验结果

按照试验设计开展了4组测试工作,测试指标包括底流浓度和沉降速率,并根据测试结果开展了固体通量的计算工作,测试结果如表1所示。

表1 沉降试验测试结果

Table 1

| 序号 | 料浆质量浓度/% | APM/(g·t-1) | 对照组 | 测试组 | ||||

|---|---|---|---|---|---|---|---|---|

| 沉降速率/(cm·min-1) | 底流浓度/% | 固体通量/(t·hr-1·m-2) | 沉降速率/(cm·min-1) | 底流浓度/% | 固体通量/(t·hr-1·m-2) | |||

| 1 | 10 | 10 | 31.57 | 58.10 | 2.03 | 39.00 | 64.10 | 2.51 |

| 2 | 10 | 15 | 37.98 | 57.80 | 2.45 | 45.56 | 63.80 | 2.93 |

| 3 | 12 | 10 | 34.91 | 59.30 | 2.74 | 42.55 | 65.50 | 3.34 |

| 4 | 12 | 15 | 35.00 | 58.10 | 2.75 | 45.73 | 64.40 | 3.59 |

3.2 结果分析

(1)对表1沉降速率结果进行分析可知:对照组沉降速率介于31.57~37.98 cm/min之间,平均值为34.86 cm/min,而测试组沉降速率介于38.99~45.73 cm/min之间,平均值为43.21 cm/min,平均增幅为24%,绝对增量为8.3 cm/min,表明受低频扰动耙架的影响,尾砂絮凝沉降过程明显加快,平均增幅达24%。

(2)对表1底流浓度结果进行分析可知:对照组底流浓度介于58.1%~59.3%之间,平均值为58.3%;而测试组底流浓度介于63.8%~65.5%之间,平均值为64.5%。测试组较对照组平均增幅达10.5%,绝对增量为6.1%,表明受低频扰动耙架的影响,絮凝沉降的沉实区浓度显著增加。

(3)对表1固体通量结果进行分析可知:对照组固体通量介于2.03~2.75 t/(hr

从沉降速率、底流浓度和固体通量的测试结果来看,对絮凝沉降进行适当的干扰,有助于提高其沉降速率和底流浓度。

3.3 絮凝沉降机理与微超孔隙水

通过试验现象和测试结果可知,絮凝沉降出现“高沉速—低底流”现象,分析其形成原因如下:

(1)絮凝沉降过程中,絮凝剂高分子聚合物与尾砂细小颗粒形成的“超级”絮团,客观上减小了絮团颗粒的总比表面积,使得沉降过程中,受到水阻力作用力大幅减小,因而沉降速率增大。

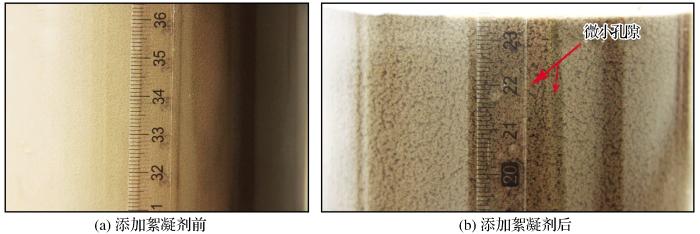

(2)在沉降过程中絮团之间的相互接触、沉实和挤压促使絮团中的“包裹水”排除,随着絮凝沉降过程的进行,絮团之间的接触越来越密切,沉实作用越来越显著,絮团中“包裹水”的疏水通道不断受到上部絮团的堵塞,最终导致絮团中的“包裹水”完全不能排出而达到沉实平衡。“包裹水”的存在增大了沉实区的孔隙率,这一机制宏观上导致了絮凝沉降底流浓度的降低,同时,这一堵塞效应也引起了沉降区域(或沉实区域)微弱的超孔隙水压力,如图2(b)所示。

图2

图2

絮凝沉降前(a)和沉降后(b)砂浆中颗粒形态

Fig.2

Particle appearance contrast before and after flocculation in slurry

3.4 动态干扰作用机理分析

通过试验现象和试验结果,对于低频扰动絮凝沉降能够显著改善底流浓度并加速沉降过程这一现象的原因进行初步分析。

在动态干扰沉降过程中,低频扰动的干扰作用可划分为3种,即重塑作用、逸散作用和疏导作用。

(1)重塑作用。重塑作用主要发生在沉降区段,絮团受扰动力的影响,在自由沉降过程中,絮团最初形态受到干扰而发生空间几何形状的变化,这一变化在一定程度上促使絮团中的“包裹水”排出,改变了絮团在沉降过程中的受力状态,促进絮团快速沉降。

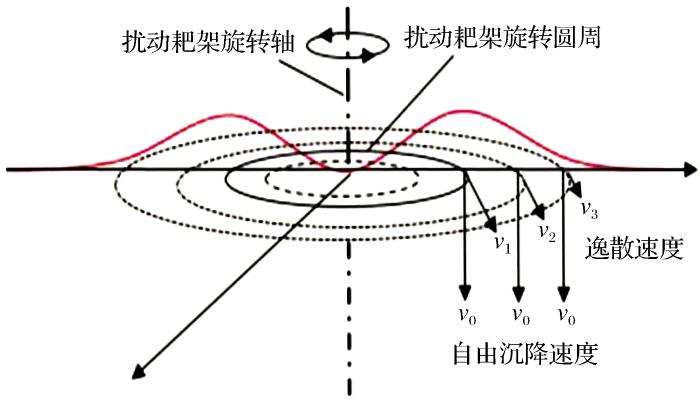

(2)逸散作用。扰动耙架在沉降区域中会形成一个速度场,这个速度场以扰动耙架旋转轴为中心,在以旋转轴为法线的平面上形成速度梯度。其中,耙架杆旋转的圆周上具有最大的逸散速度,絮团一方面受其自身有效自重应力的作用而发生垂直向下的自由沉降,产生自由沉降速度,另一方面在逸散作用下,形成水平的逸散速度,产生水平方向的运动分量,如图3所示。

图3

显然,在逸散作用下,絮团的运动轨迹将不再是垂直向下的自由沉降,在自由沉降速度和逸散速度的作用下,沉降轨迹将变得复杂,由于受边界条件的制约,在沉降空间内,絮团颗粒将产生涡流运动,这种运动一方面促进了絮团的重塑作用,另一方面絮团运动方向的不断变化,促进了下部沉降区的“微超孔隙水”的外排,因而宏观上提高了沉降速率。

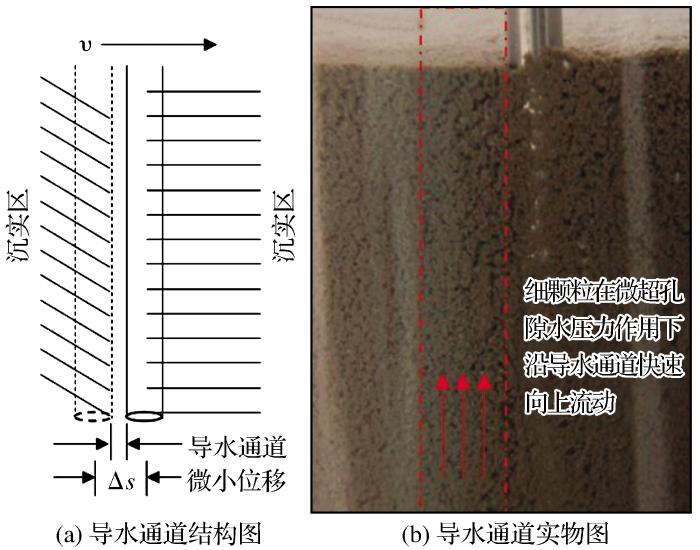

(3)疏导作用。疏导作用主要体现在扰动耙架对沉实区域的影响,在扰动耙架旋转圆周附近的沉实区域,耙架在微小的时间段

图4

图4

扰动架的疏导作用与导水通道

Fig.4

Dredging action and water guide channel by disturbing frame effect

4 结论

(1)开展了动态絮凝沉降(测试组)和静态絮凝沉降试验(对照组),试验结果表明,受低频扰动耙架的影响,尾砂絮凝沉降过程明显加快,平均增幅为24%,底流浓度明显提高,增幅为10%。

(2)絮凝沉降时,絮团中的“包裹水”和絮团间的“孔隙水”不能有效排出是影响沉降速率的重要原因,“包裹水”和“孔隙水”的存在,增大了沉实区域的孔隙率,是导致底流浓度降低的原因所在。

(3)动态絮凝沉降过程中的扰动作用,可划分为3种,分别为重塑作用、逸散作用和疏导作用。重塑作用是低频耙架在絮团沉降过程中不断改变絮团的空间几何形态,促进了“包裹水”外排,引起沉降速率的增加;逸散作用是低频旋转耙架在沉降空间形成速度场,改变了絮团的沉降路径,促进重塑作用过程和“微超孔隙水”的排出,因而对沉降速率有所影响;疏导作用是耙架微小运动位移使其形成导水通道,促进“孔隙水”的上排,减小了沉实区的孔隙率,提高了底流浓度。

参考文献

矿山充填理论与技术

[M].

Mine Filling Theory and Technology

[M].

The impact of polyacrylamide flocculant solution age on flocculation performance

[J].

The effect of flocculant solution transport and addition conditions on feedwell performance in gravity thickeners

[J].

Investigation of the effect of polymer structure type on flocculation,rheology and dewatering behaviour of kaolinite dispersions

[J].

Cemented backfilling technology with unclassified tailings based on vertical sand silo

[J].

全尾砂絮凝沉降参数GA-SVM优化预测模型研究

[J].

Study on GA-SVM optimal prediction model on flocculating sedimentation parameter of unclassified tailings

[J].

基于尾砂沉降与流变特性的深锥浓密机压耙分析

[J].

Pressure rake analysis of deep cone thickeners based on tailings’ settlement and rheological characteristics

[J].

立式砂仓尾砂浆液絮凝沉降试验研究

[J].

Experimental study on flocculating sedimentation of tailings slurry in a vertical sand tank

[J].

全尾砂动态絮凝沉降试验研究

[J].

Experimental study on dynamic flocculating sedimentation of unclassified tailings

[J].

基于宾汉姆体的高浓度尾砂浆剪切变稀规律研究

[J].

Shearing thinning behavior of high concentration slurry based on Bingham model

[J].

极细粒级尾砂絮凝沉降规律试验研究

[J].

et al.Experimental study on flocculation sedimentation of fine tailings

[J].23(Supp

.

全尾砂絮凝沉降规律及其机理

[J].

Rule and mechanism of flocculation sedimentation of unclassified tailings

[J].

尾矿动态浓密过程中底流浓度主要影响因素研究

[J].

Study on main factors of underflow concentration in the dynamics thickening process of tailings

[J].

全尾砂沉降浓缩试验研究

[J].

Experimental study on sedimentation and concentration of unclassified tailings

[J].

Sulphate effect on the early age strength and self-desiccation of cemented paste backfill

[J].

In situ measurements of surficial mud strength:A new vane tester suitable for soft intertidal muds

[J].

超细全尾砂絮凝沉降实验研究

[J].

Experimental study on flocculating sedimentation of ultra-fine unclassified tailings

[J].

深锥浓密机搅拌刮泥耙扭矩力学模型

[J].

Mechanical model of scraper rake torque in deep-cone thickener

[J].

膏体充填尾矿浓密规律初探

[J].

A primary discussion on the thickening law of paste-filling

[J].

甘公网安备 62010202000672号

甘公网安备 62010202000672号