PDF(4865 KB)

PDF(4865 KB)

PDF(4865 KB)

PDF(4865 KB)

PDF(4865 KB)

PDF(4865 KB)

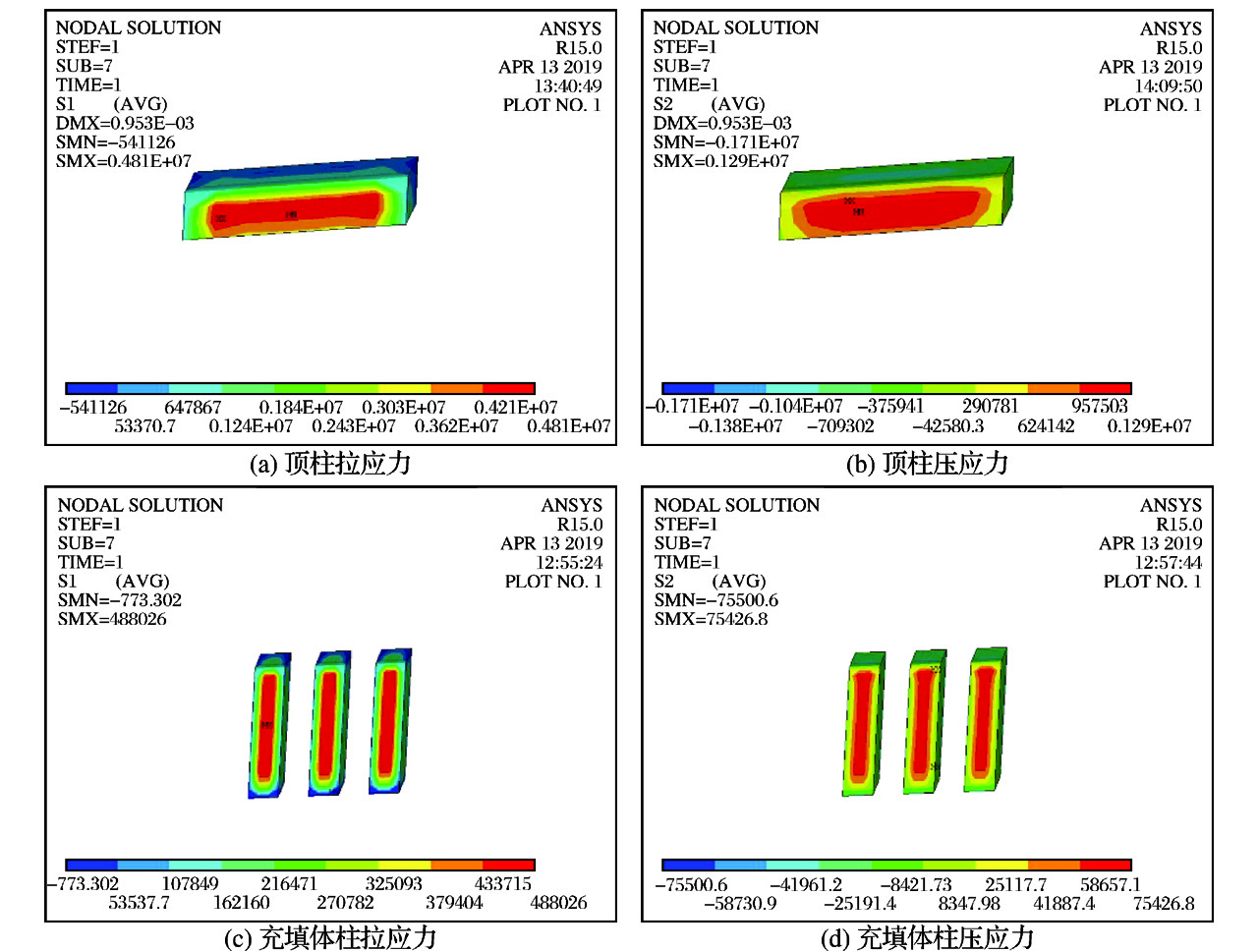

穰家垅银矿大规模充填采矿采场结构参数优化研究

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Study on the Optimization of Stope Structure Parameters in the Large-scale Backfilling Mining of Rangjialong Silver Mine

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |