PDF(2729 KB)

PDF(2729 KB)

PDF(2729 KB)

PDF(2729 KB)

PDF(2729 KB)

PDF(2729 KB)

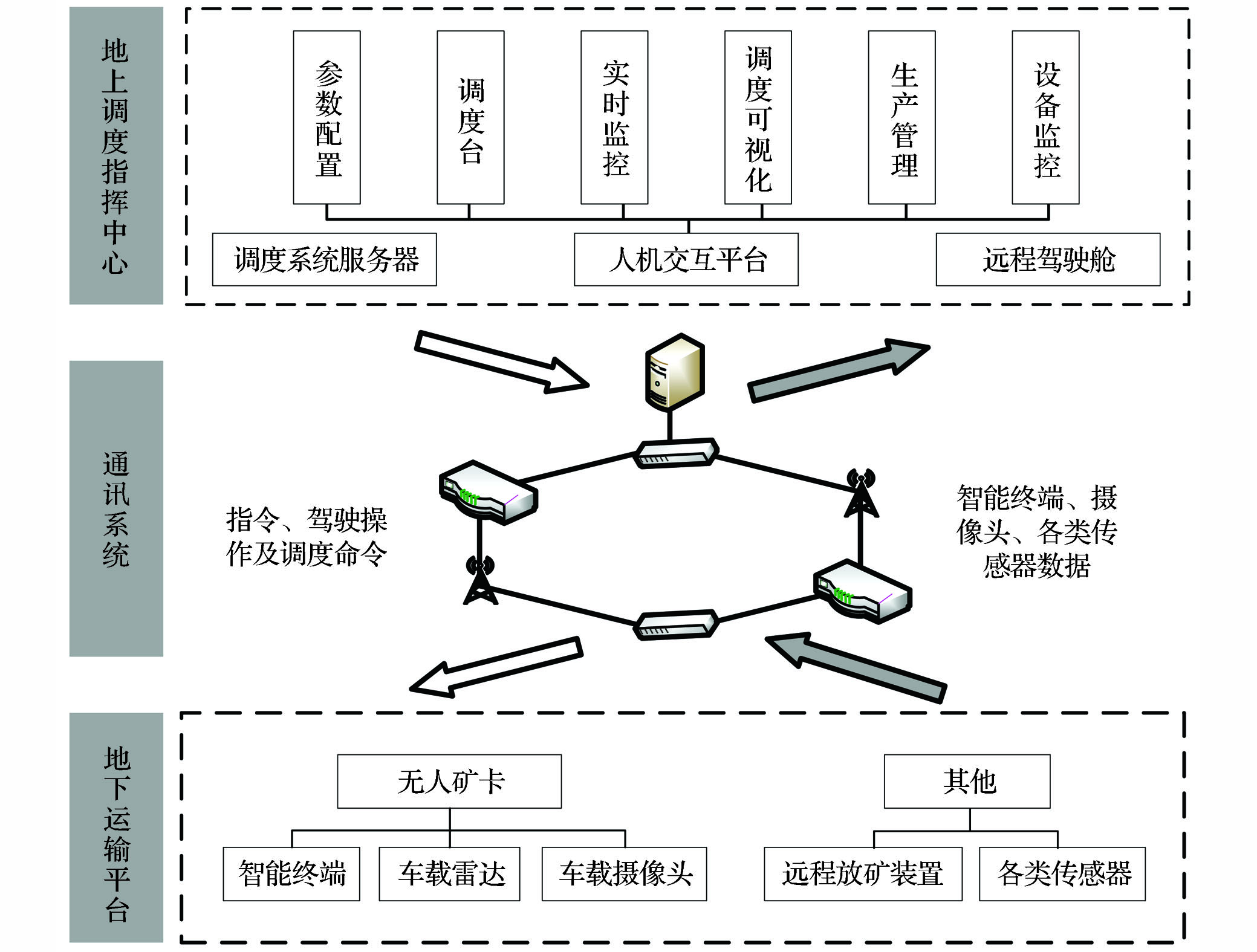

地下矿卡智能调度与生产管理系统设计及应用

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Design and Application of Intelligent Dispatching and Production Management System for Underground Mining Trucks

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |