PDF(2377 KB)

PDF(2377 KB)

PDF(2377 KB)

PDF(2377 KB)

PDF(2377 KB)

PDF(2377 KB)

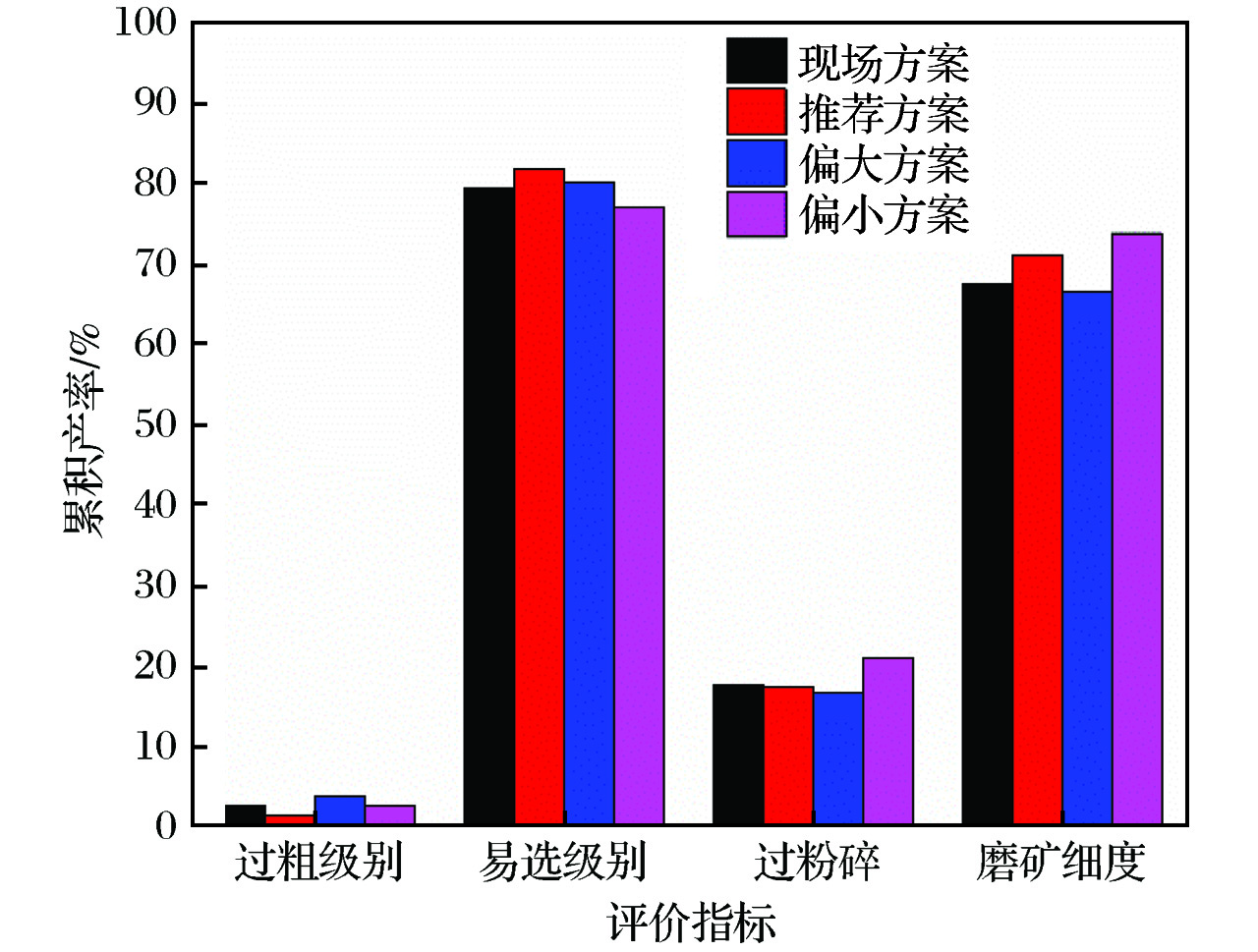

江西某铜矿大型球磨机介质制度优化试验研究

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Experimental Study on Optimizing the Media System of Large-scale Ball Mill in a Copper Mine in Jiangxi Province

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |