PDF(1451 KB)

PDF(1451 KB)

PDF(1451 KB)

PDF(1451 KB)

PDF(1451 KB)

PDF(1451 KB)

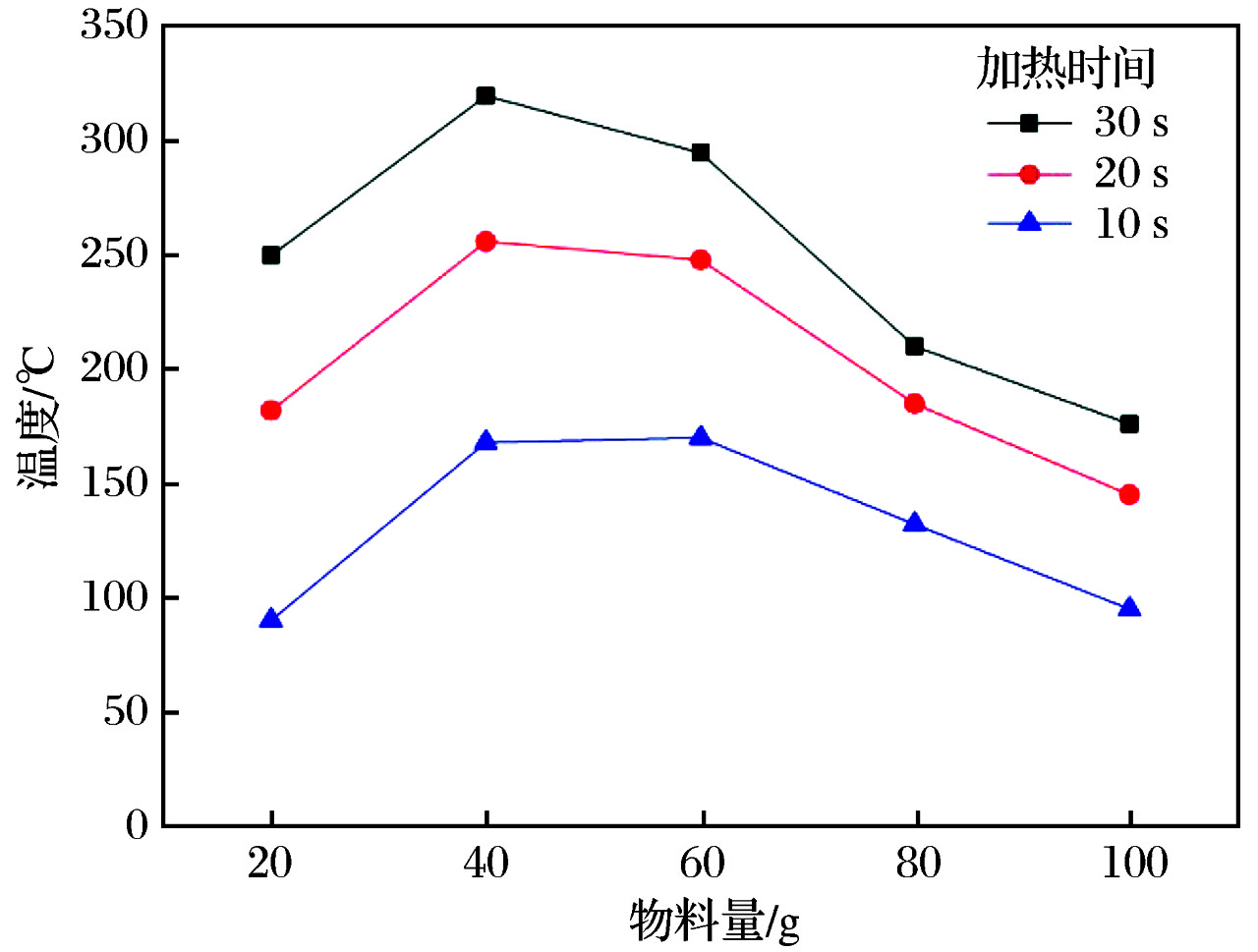

脉冲微波助磨工艺参数对钛铁矿升温性能的影响研究

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Study of Effect of Pulsed Microwave Assisted Grinding Process Parameters on the Ilmenite Heating Performance

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |