PDF(3322 KB)

PDF(3322 KB)

PDF(3322 KB)

PDF(3322 KB)

PDF(3322 KB)

PDF(3322 KB)

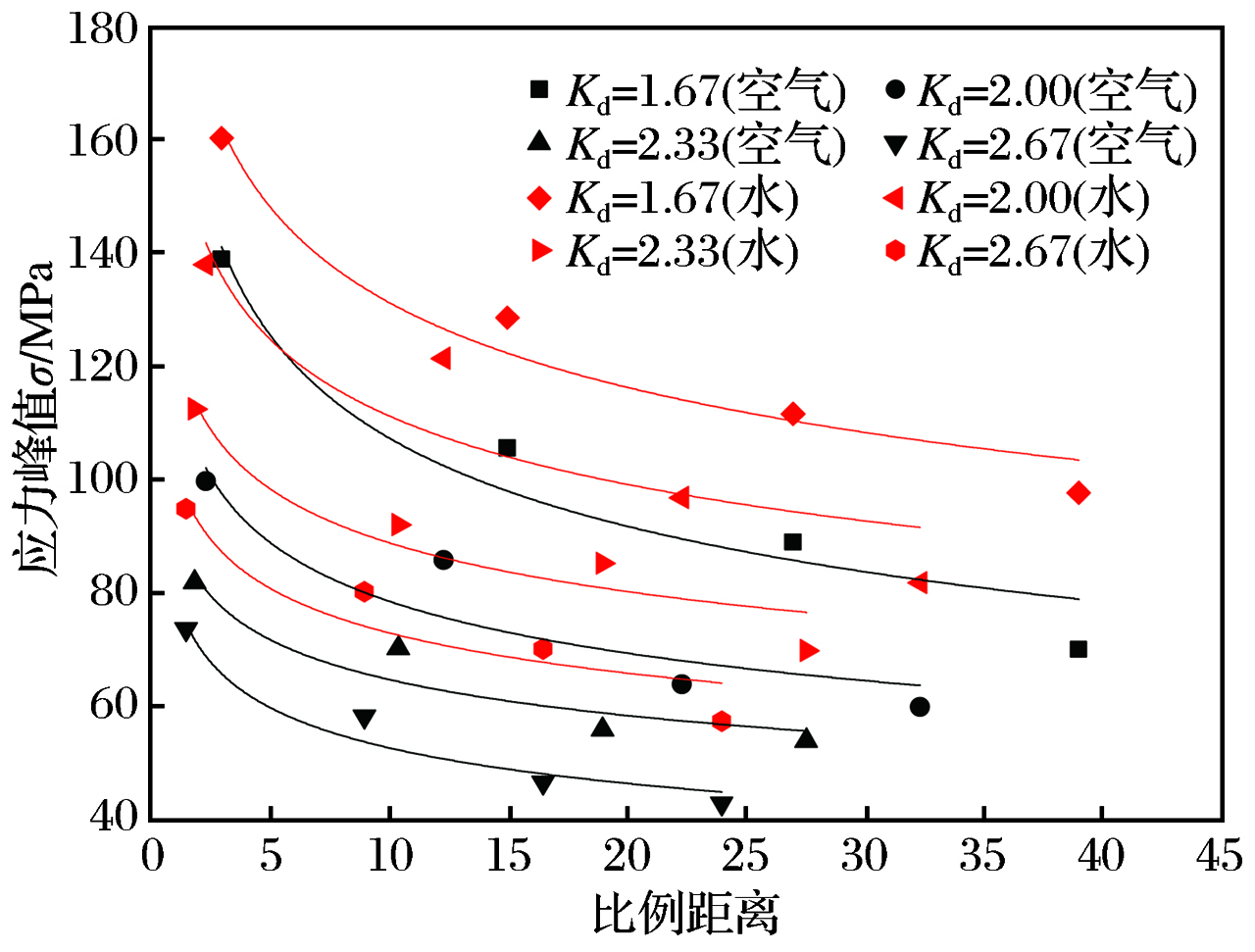

煤矿下山巷道水与空气不耦合装药爆破技术对比研究

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Water-uncouple Charge Blasting Technology for Diphead Roadway in Coalmine

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |