PDF(4576 KB)

PDF(4576 KB)

PDF(4576 KB)

PDF(4576 KB)

PDF(4576 KB)

PDF(4576 KB)

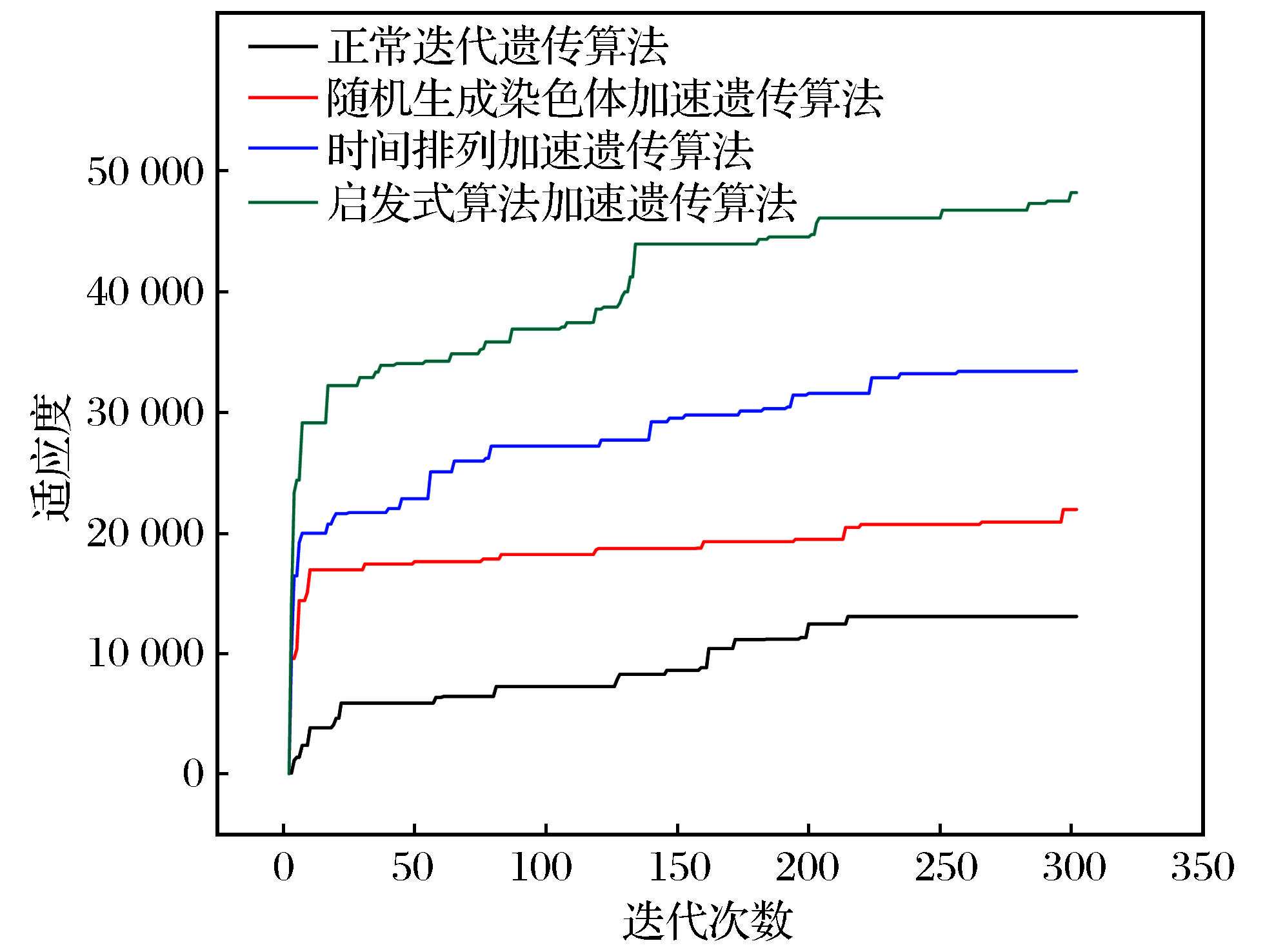

基于启发式遗传算法的地下采场作业计划优化模型

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Optimization Model of Underground Stope Working Plan Based on Heuristic Genetic Algorithm

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |