PDF(3305 KB)

PDF(3305 KB)

PDF(3305 KB)

PDF(3305 KB)

PDF(3305 KB)

PDF(3305 KB)

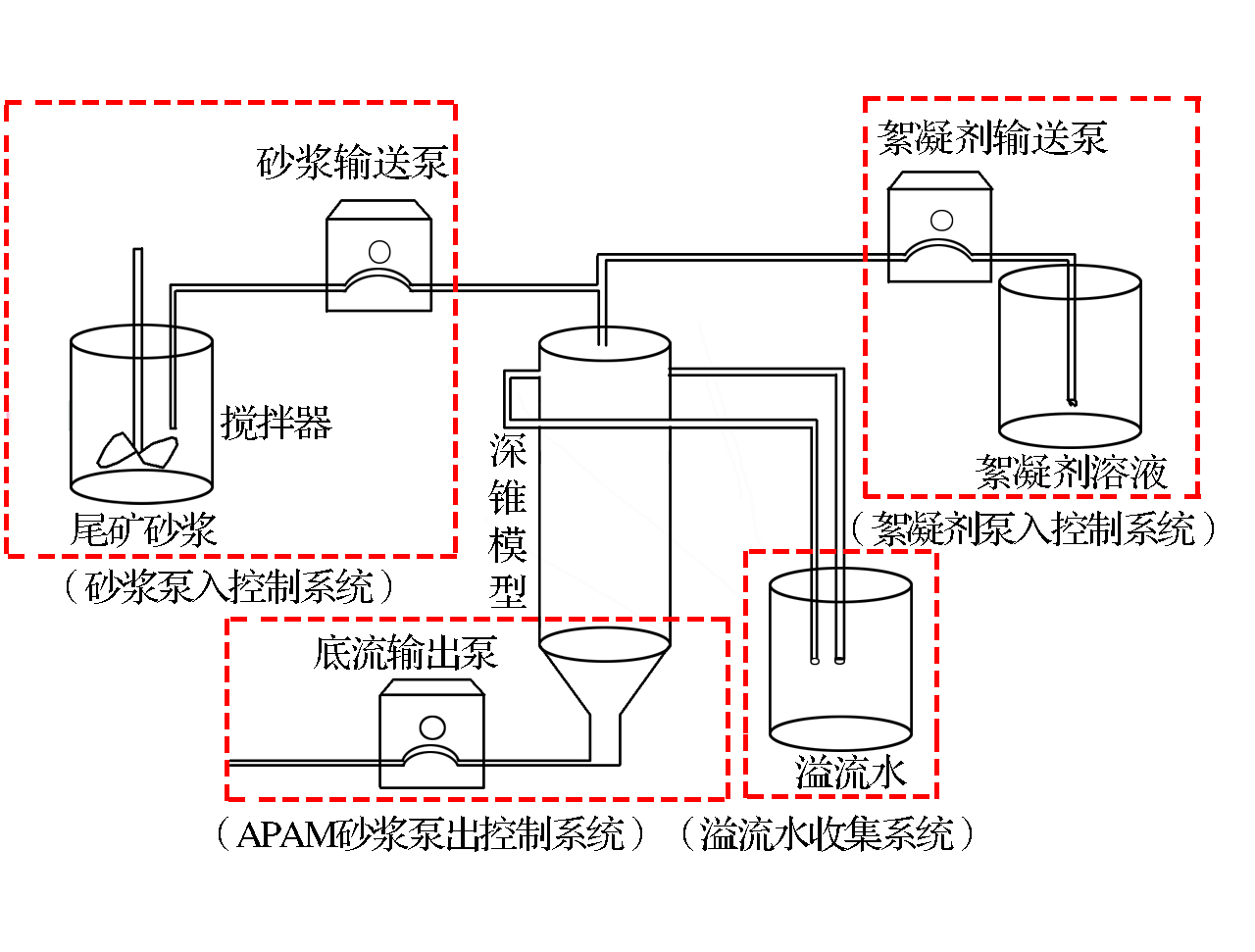

APAM对全尾砂胶结充填体早期强度影响研究

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Influence of APAM on Early Age Strength of Cemented Backfill Based on Unclassified Tailings

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |