在巷道开挖时,围岩初始应力状态被打破形成二次应力场,进而产生应力集中现象,当应力集中到一定程度后会引发围岩破裂,形成一个围岩“破碎带”,称之为围岩松动区。松动区内矿岩松动破碎,可截割性较好。松动区厚度体现了作业面周围矿岩的破裂范围,是决定非爆机械化开采可行性的重要参数。随着深部开采逐渐成为地下矿山开采的新趋势,非爆机械化开采方法作为常规钻爆开挖的替代方法之一,能够显著提高破岩效率并促进地下资源的安全、高效、绿色开发。

国内外学者从理论和试验2个方面对松动区厚度开展了一系列研究,现有研究表明:松动区厚度主要受岩石性质、地应力、地质条件和开挖参数等因素的影响(Wang et al.,2019;Martini et al.,1997;Martino,2004;Read et al.,2004)。部分学者研究了岩石单轴抗压强度、埋深、巷道跨度和岩体性质等对松动区厚度的影响(刘刚等,2021;黄锋等,2016;吴清星等,2012)。关于围岩松动区的其他影响因素,靖洪文等(1999)利用实测数据研究了围岩松动区与围岩应力、围岩强度、采深、临界采深和采动等影响因素之间的关系。还有学者通过有限元、离散元和材料点休眠等方法建立了松动区模型并用于模拟松动区的形成规律及分布特征(Han et al.,2020;Alcolea et al.,2019;Gao et al.,2020;Farahmand et al.,2020)。

随着探测技术的进步,一些新的松动区厚度测试方法被引入到采矿行业,研究人员利用超声波探测法、多点位移计量测法和地质雷达探测法等多种松动圈测试方法对不同埋深和围岩等级条件下的松动区进行了研究(吴涛等,2015;黄锋等,2016;孟庆彬等,2010;Walton et al.,2015)。一些学者运用已有的理论建立了松动区范围的理论计算方法。如:李伟利等(2011)根据霍克布朗准则提出了松动区半径计算公式并进行了现场测试;赵国彦等(2016)引入量纲分析法,选取多个物理量构建了松动区厚度的预测模型。在松动区预测方面,有学者通过逐步回归分析法、人工鱼群算法、粒子群算法、遗传算法和神经网络等数值算法建立了松动区厚度的预测模型并进行了现场验证(马荣田,2006;孙希奎等,2016;胡军等,2014;马文涛,2007;许国安等,2005;高玮等,2002;江权等,2007)。但现有的松动区预测模型考虑的影响因素较少,缺少各种开采条件下的开采数据及松动区厚度数据,并且未建立合理的机械化开采判据。

本文通过回归分析建立了以单轴压缩强度、岩体质量等级、埋深、岩石容重和开挖跨度为影响因素的松动区厚度预测模型。利用熵权法对各影响因素进行权重评价,将开磷马路坪矿现场实测的松动区厚度数据与模型计算得到的预测数据进行对比,验证了开磷马路坪矿非爆机械化开采的可行性和合理性,并建立了以矿岩开挖松动区厚度为依据的非爆机械化开采判据,为实现硬岩矿山非爆机械化连续开采和安全、高效、绿色开发提供理论和实践依据。

1 回归分析

1.1 试验数据

在工程实践中收集到69组关于矿岩松动区的基础数据,分别来自湘西金矿、玲珑金矿、凡口铅锌矿和开阳磷矿等矿山,包含单轴抗压强度σc、岩体质量等级F、埋深H、岩石容重γ、开挖跨度S和松动区厚度L(表1)。其中,松动区厚度通过钻孔超声波探测和钻孔电视监测方法实测获得。将搜集到的现场数据进行分析处理及回归拟合,再由得到的回归系数建立松动区厚度与5个影响因素之间的函数关系式,从而得到松动区厚度的预测模型。

表1 矿山现场测试数据

Table 1

| 序号 | 单轴抗压强度σc/MPa | 岩体质量等级F | 埋深H/m | 岩石容重 γ/(kN·m-3) | 开挖跨度S/m | 松动区厚度L/m | 序号 | 单轴抗压强度σc/MPa | 岩体质量等级F | 埋深 H/m | 岩石容重γ/(kN·m-3) | 开挖跨度S/m | 松动区厚度L/m |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 10.50 | 3.0 | 370 | 28.8 | 3.5 | 1.000 | 36 | 22.40 | 3.5 | 610 | 27.3 | 3.6 | 1.750 |

| 2 | 10.10 | 4.0 | 305 | 31.0 | 3.2 | 1.300 | 37 | 21.96 | 4.5 | 620 | 26.1 | 3.6 | 2.120 |

| 3 | 9.10 | 4.0 | 420 | 27.5 | 3.2 | 1.400 | 38 | 25.64 | 4.0 | 640 | 26.9 | 3.6 | 1.980 |

| 4 | 10.50 | 3.0 | 350 | 29.4 | 3.2 | 1.200 | 39 | 21.96 | 4.5 | 660 | 25.4 | 3.6 | 2.200 |

| 5 | 12.60 | 4.0 | 510 | 25.9 | 3.7 | 1.400 | 40 | 25.64 | 3.0 | 615 | 27.1 | 3.6 | 1.500 |

| 6 | 12.60 | 3.0 | 403 | 27.9 | 2.9 | 1.300 | 41 | 16.80 | 4.5 | 670 | 24.6 | 3.6 | 2.350 |

| 7 | 11.90 | 3.0 | 293 | 31.5 | 3.5 | 1.100 | 42 | 25.64 | 3.0 | 685 | 27.3 | 3.6 | 1.700 |

| 8 | 13.30 | 4.0 | 410 | 27.8 | 3.2 | 1.400 | 43 | 16.80 | 4.5 | 700 | 23.4 | 3.6 | 2.550 |

| 9 | 11.20 | 3.0 | 450 | 26.9 | 3.0 | 1.200 | 44 | 25.64 | 3.5 | 675 | 28.4 | 3.8 | 2.100 |

| 10 | 62.40 | 2.0 | 362 | 29.0 | 2.6 | 0.600 | 45 | 16.80 | 5.0 | 705 | 23.1 | 3.8 | 2.850 |

| 11 | 11.20 | 3.0 | 315 | 30.6 | 2.8 | 1.100 | 46 | 25.64 | 3.0 | 700 | 28.4 | 3.8 | 1.780 |

| 12 | 101.60 | 1.0 | 460 | 26.7 | 3.2 | 0.400 | 47 | 16.80 | 5.0 | 650 | 24.2 | 6.0 | 3.450 |

| 13 | 13.30 | 3.0 | 125 | 29.3 | 2.8 | 1.100 | 48 | 25.64 | 4.5 | 680 | 28.3 | 3.8 | 2.350 |

| 14 | 28.00 | 3.0 | 310 | 30.8 | 3.2 | 0.800 | 49 | 21.96 | 5.0 | 630 | 26.3 | 4.0 | 2.600 |

| 15 | 18.80 | 3.0 | 340 | 29.7 | 3.4 | 1.300 | 50 | 52.00 | 3.0 | 700 | 28.4 | 4.2 | 1.700 |

| 16 | 10.90 | 4.0 | 665 | 24.1 | 3.6 | 1.700 | 51 | 52.00 | 3.0 | 750 | 28.4 | 4.2 | 1.700 |

| 17 | 14.30 | 4.0 | 322 | 30.3 | 4.4 | 1.500 | 52 | 52.00 | 3.0 | 690 | 28.4 | 4.2 | 1.400 |

| 18 | 9.10 | 5.0 | 450 | 26.9 | 3.4 | 2.000 | 53 | 52.00 | 3.0 | 690 | 28.4 | 4.6 | 1.500 |

| 19 | 16.80 | 3.0 | 249 | 23.9 | 3.2 | 1.000 | 54 | 40.00 | 3.0 | 690 | 24.6 | 4.6 | 1.600 |

| 20 | 22.40 | 3.0 | 296 | 31.4 | 3.4 | 1.200 | 55 | 25.64 | 3.0 | 615 | 28.3 | 3.6 | 1.500 |

| 21 | 23.80 | 3.0 | 178 | 30.1 | 2.6 | 1.200 | 56 | 16.80 | 4.5 | 670 | 24.2 | 3.6 | 2.350 |

| 22 | 11.96 | 4.0 | 268 | 24.8 | 3.4 | 1.400 | 57 | 25.64 | 3.0 | 685 | 28.3 | 3.6 | 1.700 |

| 23 | 110.20 | 1.0 | 180 | 29.8 | 2.8 | 1.000 | 58 | 34.37 | 4.0 | 660 | 27.2 | 4.5 | 1.650 |

| 24 | 14.30 | 3.0 | 236 | 24.7 | 3.0 | 1.200 | 59 | 147.89 | 5.0 | 660 | 32.3 | 4.0 | 2.340 |

| 25 | 13.30 | 3.0 | 321 | 30.4 | 3.0 | 1.100 | 60 | 71.26 | 3.0 | 600 | 27.1 | 3.8 | 1.100 |

| 26 | 11.20 | 3.0 | 97 | 28.3 | 2.6 | 1.100 | 61 | 39.19 | 3.0 | 1 000 | 28.6 | 4.6 | 1.930 |

| 27 | 73.60 | 2.0 | 340 | 29.7 | 3.0 | 0.800 | 62 | 158.83 | 5.0 | 800 | 28.1 | 5.6 | 2.900 |

| 28 | 13.30 | 4.0 | 450 | 26.9 | 3.6 | 1.600 | 63 | 147.89 | 4.0 | 800 | 32.2 | 5.6 | 2.690 |

| 29 | 32.20 | 2.0 | 340 | 29.7 | 3.2 | 0.700 | 64 | 109.50 | 3.0 | 800 | 26.7 | 5.6 | 2.270 |

| 30 | 10.10 | 5.0 | 470 | 26.5 | 4.0 | 2.200 | 65 | 142.16 | 3.0 | 370 | 31.1 | 3.4 | 1.200 |

| 31 | 14.30 | 3.0 | 420 | 27.5 | 3.6 | 1.100 | 66 | 142.16 | 3.0 | 450 | 31.1 | 3.4 | 1.400 |

| 32 | 11.90 | 4.0 | 520 | 25.8 | 3.8 | 1.700 | 67 | 142.16 | 3.0 | 530 | 31.1 | 3.4 | 1.550 |

| 33 | 9.10 | 5.0 | 470 | 26.5 | 3.6 | 2.100 | 68 | 142.16 | 3.0 | 680 | 31.1 | 3.4 | 1.800 |

| 34 | 10.10 | 4.0 | 467 | 26.6 | 3.4 | 1.800 | 69 | 142.16 | 3.0 | 780 | 31.1 | 3.4 | 1.975 |

| 35 | 16.80 | 4.5 | 600 | 25.4 | 3.6 | 2.250 |

1.2 回归模型

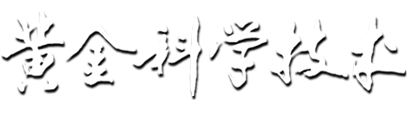

将岩石单轴抗压强度、岩体质量等级、埋深、岩石容重和开挖跨度5个影响因素进行组合,建立了预测松动区厚度的量纲统一化公式。将岩石单轴抗压强度、岩体质量等级、埋深和岩石容重组合为与松动区厚度量纲一致的岩性指标,将岩体质量等级和开挖参数组合为与松动区厚度量纲一致的开挖参数指标。采用多元回归分析方法,将岩性指标和开挖参数指标分别作为X轴和Y轴,得到2个指标与松动区厚度之间的函数关系式:

式中:L为松动区厚度;β1、β2和β3为回归系数;

图1

1.3 模型验证

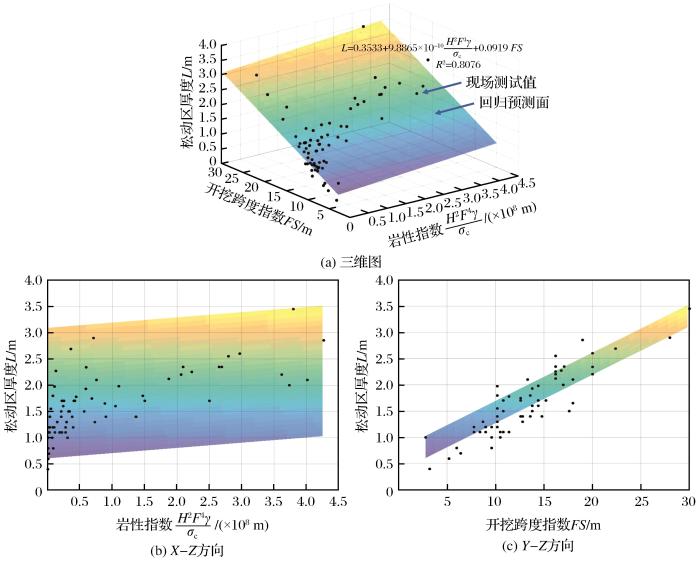

通过

式中:

图2

图2

现场测试值与预测值散点对比图

Fig.2

Comparison diagram of scatter plot between field test values and predicted values

2 熵权法评价权重

熵权法是一种客观赋权法,其仅依赖于数据本身的离散性,根据指标变异性的大小来确定客观权重。通过使用熵权法对5个影响因素进行权重评价,确定各因素对松动区厚度的影响大小。熵权法赋权步骤如下:

(1)数据标准化。将各个指标的数据进行标准化处理,将不同量纲的指标同量纲化,给定K个指标X1,X2,…,XK,其中Xi={x1,x2,…,xn},各指标数据标准化后的值为X ΄1,X ΄2,…,X ΄K。数据标准化公式为

(2)计算各个指标信息熵。若某个指标的信息熵Ej越小,表明指标值的变异程度越大,指标提供的信息量越多,在综合评价中所能起到的作用也越大,其权重也就越大。相反,某个指标的信息熵越大,表明指标值的变异程度越小,指标提供的信息量越少,在综合评价中所起到的作用也越小,其权重也就越小。先按照

式中:

(3)计算各个指标权重。根据

按照熵权法计算权重的步骤,最终确定单轴抗压强度、岩体质量等级、埋深、岩石容重和开挖跨度5个影响因素对于松动区厚度的影响权重(表2),并且依次对各个影响因素的影响权重进行排序。

表2 松动区厚度影响因素权重

Table 2

| 影响因素 | 权重 |

|---|---|

| 单轴抗压强度σc | 0.5865 |

| 岩体质量等级F | 0.0607 |

| 埋深H | 0.0929 |

| 岩石容重γ | 0.1024 |

| 开挖跨度S | 0.1574 |

结果表明:单轴抗压强度对于松动区厚度的影响权重最大,岩体质量等级对于松动区厚度的影响权重最小,埋深、岩石容重和开挖跨度对于松动区厚度的影响权重依次增大。因此,岩石单轴抗压强度和开挖跨度对于开挖后松动区厚度有较大影响。

3 现场测试

3.1 测试方案

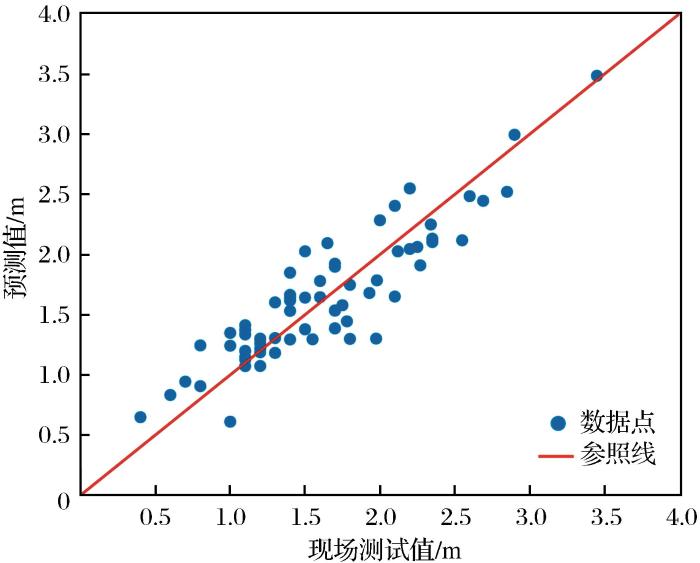

试验区域矿体位于开磷马路坪矿580 m中段下盘矿1盘区,埋深为490 m(加上地表山体,实际埋深近千米)。开挖采准巷道后,试验区域矿体存在3个自由面,在每个自由面上布置上下两排共6个监测孔,3个自由面共布置18个深度为3.5 m的监测孔,然后通过数字钻孔电视监测钻孔内部情况。在数字钻孔电视图像分析软件中嵌入数字图像处理模块,对裂隙进行识别和表征,通过观察沿钻孔深度的裂隙分布,以确定裂隙密度的突变,突变的位置标志着原始岩体与受损岩体之间的分界点,从该点到孔口距离即为钻孔中的松动区厚度,再加上矿体外部钻孔后的垮落厚度,以此来确定各监测点实际松动区的厚度,进而确定矿柱松动区范围,监测孔布置图如图3所示。

图3

3.2 测试设备及过程

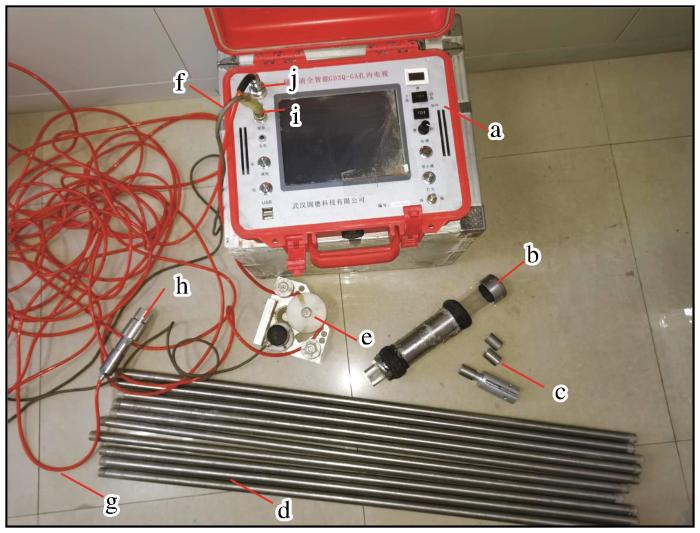

图4

图4

监测及连接设备

a-钻孔电视;b-钻孔摄像头;c-连接螺母;d-金属连接杆;e-位移罗盘;f-摄像头连接线;g-位移罗盘连接线;h-摄像头连接头;i-摄像头连接插头;j-位移罗盘连接插头

Fig.4

Monitoring and connecting devices

图5

3.3 松动区厚度测试结果

对钻孔电视监测记录的钻孔内部数据进行处理,得到上下两排各个监测孔内部松动区位置图像,通过识别监测孔内的破碎情况,确定监测孔内部松动区位置。由于监测设备故障及临近采矿扰动影响,1号孔和18号孔孔内破碎程度严重,不符合初始测试试验的要求,在计算每侧松动区厚度平均值时需要舍去。监测孔松动区厚度测量数据及计算后的平均松动区厚度数据见表3。

表3 监测孔松动区测量数据

Table 3

| 孔号 | 钻孔与水平面夹角θ/(°) | 钻孔中松动区位置L1/m | 钻孔后矿岩垮落厚度L2/m | 松动区实际厚度L3/m | 松动区平均厚度L4/m |

|---|---|---|---|---|---|

| 1 | 0 | 3.26 | 0.15 | 3.41(舍去) | 2.33 (左侧:1号~6号孔) |

| 2 | 0 | 2.56 | 0.10 | 2.66 | |

| 3 | 0 | 2.70 | 0.05 | 2.75 | |

| 4 | 0 | 1.99 | 0.12 | 2.11 | |

| 5 | 0 | 2.10 | 0.13 | 2.23 | |

| 6 | 0 | 1.66 | 0.26 | 1.92 | |

| 7 | 0 | 2.65 | 0.07 | 2.72 | 2.49 (外侧:7号~12号孔) |

| 8 | 0 | 2.15 | 0.16 | 2.31 | |

| 9 | 0 | 2.33 | 0.02 | 2.35 | |

| 10 | 0 | 2.44 | 0.18 | 2.62 | |

| 11 | 0 | 1.85 | 0.47 | 2.32 | |

| 12 | 0 | 2.22 | 0.39 | 2.61 | |

| 13 | 0 | 2.40 | 0.05 | 2.45 | 2.69 (右侧:13号~18号孔) |

| 14 | 0 | 2.70 | 0.06 | 2.76 | |

| 15 | 0 | 2.65 | 0.13 | 2.78 | |

| 16 | 0 | 2.67 | 0.12 | 2.79 | |

| 17 | 0 | 2.68 | 0 | 2.68 | |

| 18 | 0 | 3.03 | 0.13 | 3.16(舍去) |

3.4 松动区厚度预测结果

将现场测试区域的岩性及开挖基础数据代入由

表4 监测孔基础数据

Table 4

| 孔号 | 单轴抗压强度σc/MPa | 岩体质量等级F | 埋深H/m | 岩石容重γ/(kN·m-3) | 开挖跨度S/m | 平均开挖跨度S/m |

|---|---|---|---|---|---|---|

| 1 | 147.89 | 4 | 490 | 27.048 | 4.94 | 5.06 (左侧:1号~6号孔) |

| 2 | 147.89 | 4 | 490 | 27.048 | 5.21 | |

| 3 | 147.89 | 4 | 490 | 27.048 | 5.03 | |

| 4 | 147.89 | 4 | 490 | 27.048 | 4.94 | |

| 5 | 147.89 | 4 | 490 | 27.048 | 5.21 | |

| 6 | 147.89 | 4 | 490 | 27.048 | 5.03 | |

| 7 | 147.89 | 4 | 490 | 27.048 | 4.49 | 4.95 (外侧:7号~12号孔) |

| 8 | 147.89 | 4 | 490 | 27.048 | 5.46 | |

| 9 | 147.89 | 4 | 490 | 27.048 | 4.89 | |

| 10 | 147.89 | 4 | 490 | 27.048 | 4.49 | |

| 11 | 147.89 | 4 | 490 | 27.048 | 5.46 | |

| 12 | 147.89 | 4 | 490 | 27.048 | 4.89 | |

| 13 | 147.89 | 4 | 490 | 27.048 | 5.85 | 4.95 (右侧:13号~18号孔) |

| 14 | 147.89 | 4 | 490 | 27.048 | 4.81 | |

| 15 | 147.89 | 4 | 490 | 27.048 | 4.20 | |

| 16 | 147.89 | 4 | 490 | 27.048 | 5.85 | |

| 17 | 147.89 | 4 | 490 | 27.048 | 4.81 | |

| 18 | 147.89 | 4 | 490 | 27.048 | 4.20 |

3.5 非爆机械化开采判据

当松动区厚度大于2 m时,机械化开采效果更好。给定松动区厚度Lm=2 m,利用建立的

4 结论

通过收集的不同矿山松动区厚度测试数据,利用回归分析建立了基于单轴抗压强度、岩体质量等级、埋深、岩石容重和开挖跨度5个影响因素的松动区厚度预测模型,利用熵权法评价了各影响因素对于松动区厚度的影响权重,最后将松动区厚度现场测试数据与计算得到的预测值进行对比,得到如下结论:

(1)由岩性指标和开挖参数指标建立的回归预测模型具有较好的确定性系数和均方根误差,建立的松动区厚度预测模型具有较好的可靠性。回归模型显示,松动区厚度随着岩性指标和开挖参数指标的增大而增大。

(2)利用熵权法评价5个影响因素对于松动区厚度的影响权重,结果表明岩石单轴抗压强度和开挖跨度对松动区厚度有重要影响,岩石质量等级对松动区厚度的影响较小。

(3)在开磷马路坪矿进行现场试验,对采集到的松动区厚度数据进行分析处理,结果表明:本文建立的回归预测模型可以较好地预测现阶段开磷马路坪矿矿岩开挖松动区厚度,预测值满足非爆机械化开采的要求。本研究验证了现阶段开磷马路坪矿非爆机械化开采的可行性和合理性,并建立了基于矿岩松动区的非爆机械化开采判据。

http://www.goldsci.ac.cn/article/2021/1005-2518/1005-2518-2021-29-4-525.shtml

参考文献

3D modelling of the excavation damaged zone using a Marked Point Process technique

[J].

Calibration of coupled hydro-mechanical properties of grain-based model for simulating fracture process and associated pore pressure evolution in excavation damage zone around deep tunnels

[J].

Peridynamics simulation of surrounding rock damage characteristics during tunnel excavation

[J].

Evolutionary neural network model on predication of loosen zone around roadway

[J].

Combined finite-discrete element modelling of rock fracture and fragmentation induced by contour blasting during tunnelling with high horizontal in-situ stress

[J].

Support vector machine (SVM) prediction of roadway surrounding rock loose circle thickness optimized by layered fish

[J].

Field detection and theoretic analysis of loose circle of rock mass surrounding tunnel

[J].

Intelligent back analysis of rock mass parameters for large underground caverns under high earth stress based on EDZ and increment displacement

[J].

Measurement and analysis of influential factors of broken zone of deep roadways and study on its control technique

[J].

Calculation and site measurement of surrounding rock released circle base on Hoek-Brown criterion

[J].

Overview and prospect on theoretical calculation method of broken rock zone

[J].

Experimental study on the thickness of surrounding rock loose zone of roadway

[J].

A predicative study of loosening zones around roadways with least square support vector machines method with optimized parameters

[J].

Observations of brittle failure around a circular test tunnel

[J].

Excavation-induced damage studies at the Underground Research Laboratory

[J].

Roadway surrounding rock loose circle supporting theory and testing technology

[J].

20 years of excavation response studies at AECL’s Underground Research Laboratory

[J].

Thickness measurement and distribution law of loose rings of surrounding rock in large cross section semicircle arch seam gateway

[J].

Non-invasive detection of fractures,fracture zones,and rock damage in a hard rock excavation—Experience from the Äspö Hard Rock Laboratory in Sweden

[J].

Experimental investigation of rock breakage by a conical pick and its application to non-explosive mechanized mining in deep hard rock

[J].

Sensibility analysis of underground excavation stability based on the Hoek-Brown strength criterion

[J].

Surrounding rock loosing circle test based on acoustic test technology

[J].

Study on intelligent prediction of broken rock zone thickness of coal mine roadways

[J].

Prediction model for extent of excavation damaged zone around roadway based on dimensional analysis

[J].

巷道围岩松动圈预测的进化神经网络法

[J].

分层鱼群优化支持向量机预测巷道围岩松动圈厚度

[J].

隧道围岩松动圈的现场测试与理论分析

[J].

基于松动圈—位移增量监测信息的高地应力下洞室群岩体力学参数的智能反分析

[J].

深井巷道围岩松动圈影响因素实测分析及控制技术研究

[J].

基于Hoek-Brown准则的围岩松动圈计算及现场测试

[J].

围岩松动圈理论计算方法的评述与展望

[J].

巷道围岩松动区厚度的试验研究

[J].

参数优化LSSVM的巷道围岩松动圈预测研究

[J].

巷道围岩松动圈支护理论及测试技术

[J].

大断面半圆拱煤巷围岩松动圈厚度测定及分布规律

[J].

基于Hoek-Brown强度准则的洞室稳定影响分析

[J].

基于声波法测试技术的巷道围岩松动圈测定

[J].

煤矿巷道围岩松动圈智能预测研究

[J].

基于量纲分析的巷道围岩松动圈预测模型

[J].

甘公网安备 62010202000672号

甘公网安备 62010202000672号