随着工程技术的进步和矿山安全需求的提高,国内外学者对复合岩石的研究逐渐深入。基于“复合等效方法”和Mohr-Coulomb理论,阳友奎等(1990)提出复合岩石破坏准则,并通过三轴试验验证,指出复合岩石的强度特性能被精确描述,其失效模式与应力状态及方向角有关;付鹏等(2022)综合单轴压缩与声发射试验提出,复合岩石的破坏特征不是单一岩石破坏特征的直接相加,而是在荷载作用下耦合破坏的结果,强度高的硬岩能够约束强度低的软岩发生横向形变;刘晓云等(2017)研究发现,复合岩石中相似材料强度比越大,对复合岩石整体强度的影响也越大;陈宇龙等(2017)采用离散单元法求解了复合岩石交界面上的界面黏结应力,提出软硬互层岩体的强度曲线。

基于此,本文选取砂岩、矽卡岩和蛇纹岩这3类典型岩石,以强度居中的蛇纹岩分别搭配强度较高的砂岩和强度较弱的矽卡岩,组成2组相互对照的复合岩石,通过单轴压缩试验,对2种复合岩石的失效模式和力学性质进行分析(高美奔等,2016;王旭一等,2021;刘泉声等,2020;Xiao et al.,2020;杜坤等,2021),以期为不同材料组成的复合岩石的稳定性分析提供参考。

1 室内试验

1.1 试样准备

砂岩、矽卡岩和蛇纹岩均取自冬瓜山铜矿。通过取芯抛光,将岩石分别制作成尺寸为ϕ50 mm×50 mm和ϕ50 mm×100 mm的圆柱体试样。组合试样由ϕ50 mm×50 mm的单岩试样经过室温干燥后垂直叠放,在接触面用环氧树脂进行胶结后组成。试样的平行度和表面平整度分别控制在±0.05 mm和±0.02 mm以内,组合试样接触角度保持为0°。为了保证试验研究的可靠性,通过波速检测的方法,选取纵波速度相近的试样用于试验。不同岩性岩石的基本物理性质见表1。

表1 3种岩石物理性质

Table 1

| 岩石类型 | 密度/(kg·m-3) | 纵波波速/(m·s-1) | 横波波速/(m·s-1) | 泊松比 |

|---|---|---|---|---|

| 砂岩(Ss) | 3 801.23 | 3 950.43 | 0.22 | 0.22 |

| 矽卡岩(Sk) | 3 213.68 | 3 536.23 | 0.26 | 0.26 |

| 蛇纹岩(Spt) | 3 426.69 | 3 780.34 | 0.27 | 0.27 |

1.2 试验设备和方法

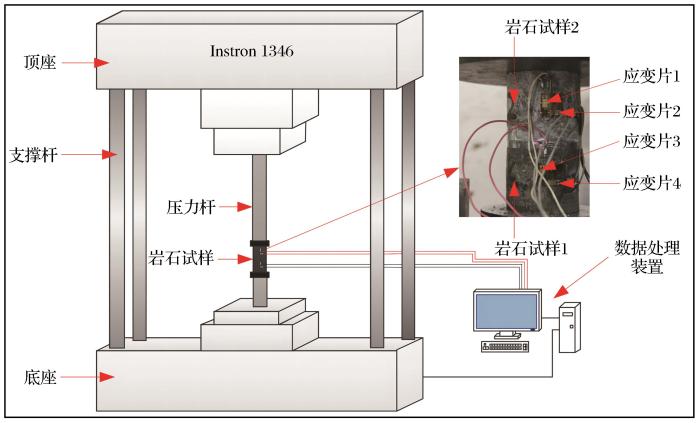

试验所用设备主要为Instron 1346,该装置由顶底座、支撑杆、应力杆以及控制和数据处理装置组成,如图1所示。

图1

2 结果和分析

2.1 应力—应变曲线

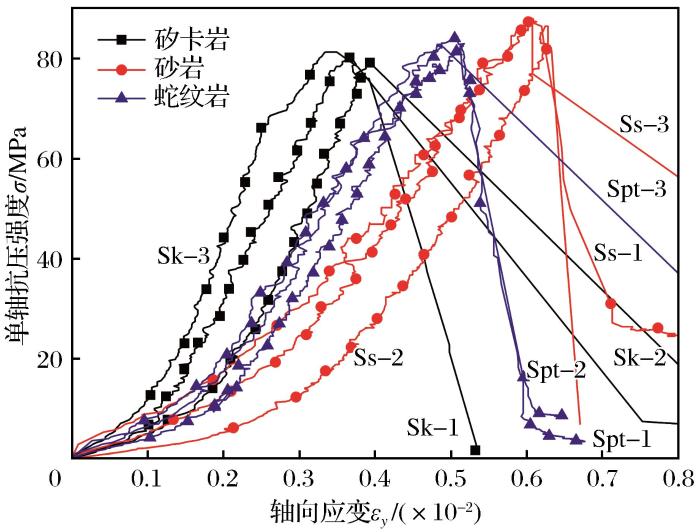

图2

表2 岩石的基本力学性质

Table 2

| 岩石类型 | 单轴压缩强度/MPa | 峰值应变 | 弹性模量/GPa |

|---|---|---|---|

| 砂岩 | 87.41 | 0.61 | 21.41 |

| 矽卡岩 | 80.25 | 0.37 | 33.81 |

| 蛇纹岩 | 83.29 | 0.50 | 25.86 |

| 蛇纹石—矽卡岩 | 80.76 | 0.42 | 26.01 |

| 蛇纹石—砂岩 | 85.48 | 0.60 | 23.43 |

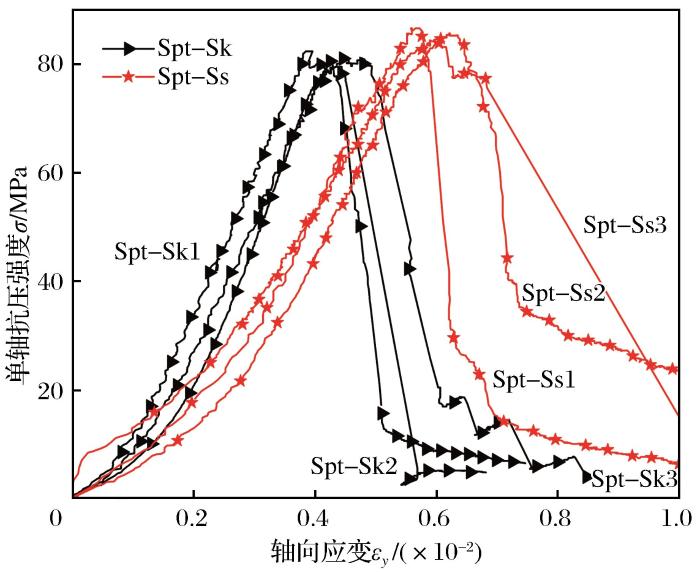

图3

岩石和复合岩石的应力—应变曲线可划分为4个阶段:(1)压密阶段,应力—应变曲线呈上凹型,此阶段几乎无裂纹产生;(2)弹性阶段,应力—应变曲线近似直线,其中弹性变形与微弹性裂隙稳定发展的临界点并不突出,随着荷载的增加,岩石内部开始产生微裂纹;(3)塑性阶段,应力达到屈服极限后,应力—应变曲线略微向下弯曲直至峰值,破裂不断发展直至岩石弯曲破坏;(4)破坏阶段,应力—应变曲线在峰值后具有显著的阶段跌落特征,表明复合岩石承载力随变形的增大迅速下降,直至完全失去承载能力。

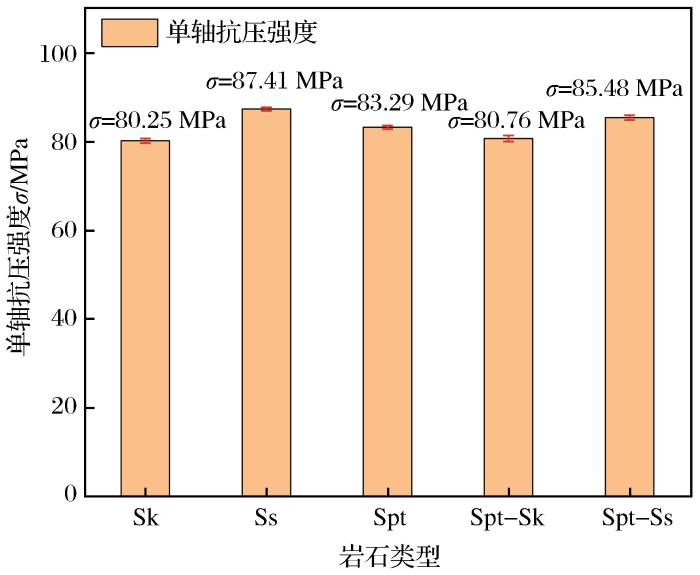

2.2 单轴抗压强度

单轴抗压强度能够反映岩石承受抗压缩的能力。如图4所示,砂岩、蛇纹岩和矽卡岩单轴抗压强度分别为87.41,83.29,80.25 MPa,砂岩的单轴抗压强度最大,其次为蛇纹岩,矽卡岩最小,说明砂岩能够承受抗压缩的能力最强。复合岩石蛇纹岩—矽卡岩在应变值为0.42时的单轴抗压强度达到80.76 MPa,而蛇纹岩—砂岩在应变值为0.60时单轴抗压强度达到85.48 MPa。砂岩的单轴抗压强度比蛇纹岩高4.95%,当砂岩与蛇纹岩复合后,复合岩石的单轴抗压强度小于砂岩而大于蛇纹岩,变化率分别为2.63%和-2.21%;蛇纹岩的单轴抗压强度比矽卡岩高3.79%,当蛇纹岩与矽卡岩复合后,复合岩石的单轴抗压强度小于蛇纹岩而大于矽卡岩,相比蛇纹岩和矽卡岩,变化率分别为0.06%和 -3.04%。由此可提出猜想,若2种单一岩石的抗压强度分别为A和C,复合岩石的抗压强度为B,则三者关系可表达为

图4

化简可得

与图4中的试验数据相比,蛇纹岩—矽卡岩复合岩石的理论单轴抗压强度为85.33 MPa,与实际值的误差率为0.18%,而蛇纹岩—砂岩复合岩石的理论单轴抗压强度为81.76 MPa,与实际值的误差率为1.23%,可知接触面为0°的复合岩石的单轴抗压强度可由

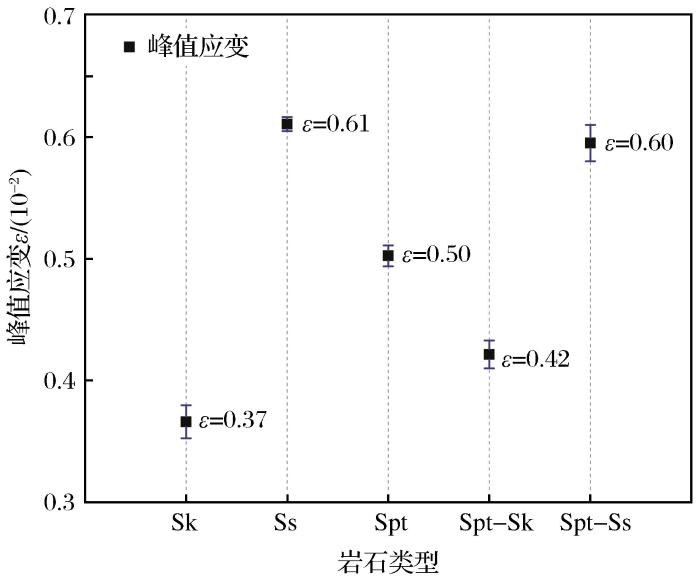

2.3 应变

应变可反映岩石受力过程中的变形情况。如图5所示,砂岩、蛇纹岩和矽卡岩的峰值应变分别为0.61、0.50和0.37,而复合岩石蛇纹岩—矽卡岩和蛇纹岩—砂岩的峰值应变分别为0.42和0.60。

图5

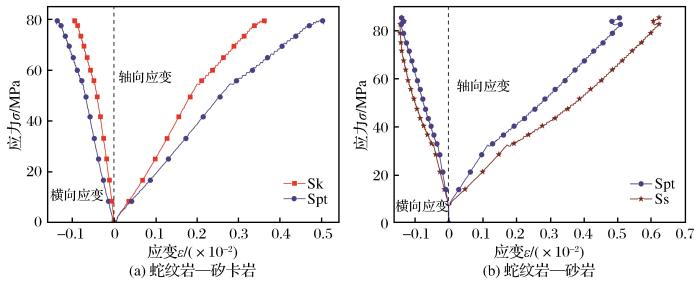

如图6所示,当应力σ为0~10 MPa时,图6(a)的压密阶段相较于图6(b)几乎不存在,岩样初始裂隙的分布情况和发育情况对压密阶段曲线特征的影响占据主要地位,若初始裂隙过少,则压密阶段不存在。当岩样的全部初始裂隙在加载状态下闭合时,图中曲线由重合至发散,此时的应力值可作为起始应力值,这表示岩样开始进入弹性阶段,横向与轴向应变曲线均具有线性减小的趋势。当应力σ为30~40 MPa时,岩样的横向应变曲线偏离线性变化,而轴向应变保持线性增长,岩样进入裂隙不稳定拓展阶段,此时的应力值可作为破坏应力点。当应力σ为80~86 MPa时,岩样轴向应力加载至峰值强度,岩样的横向与轴向应变曲线均出现了非线性的变化特征。

图6

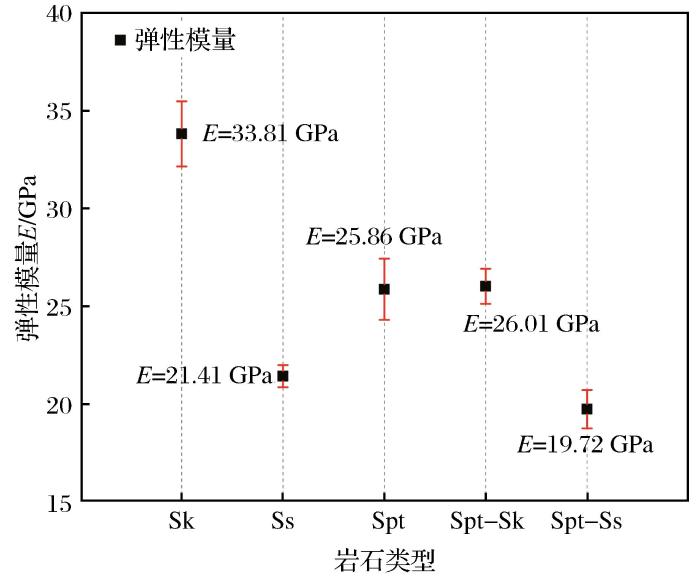

2.4 弹性模量

如图7所示,在弹性模量方面,矽卡岩的弹性模量最大,蛇纹岩次之,砂岩最小,说明矽卡岩能够承受弹性变形的能力最强。此外,在3种岩石中,砂岩的峰值应变大于其他2种岩石,破坏时的变形最大,能够承受变形的能力最强。

图7

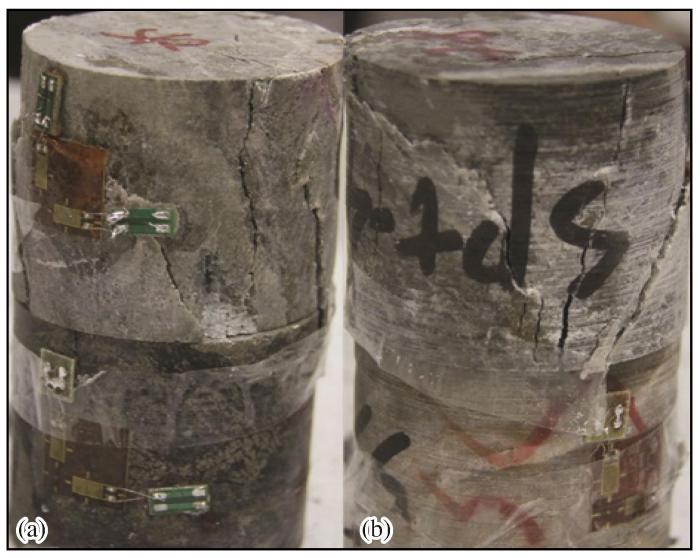

2.5 复合岩石破坏模式

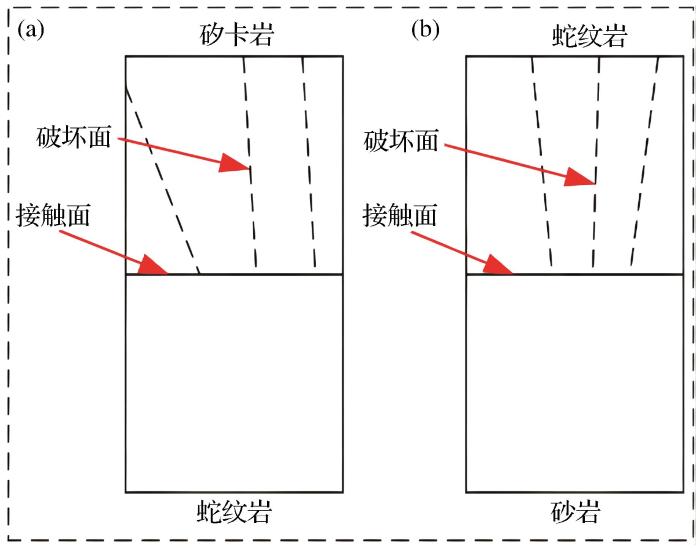

图8

图9

图9

复合岩石破坏模式示意图

(a)蛇纹岩—矽卡岩;(b)蛇纹岩—砂岩

Fig.9

Schematic diagram of failure modes of composite rocks

3 讨论

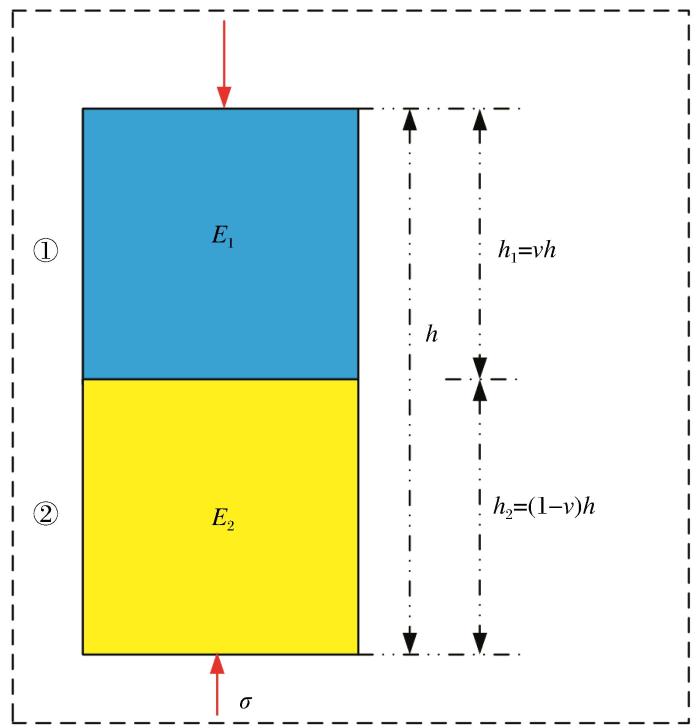

式中:σ为试验设备施加的应力;E为复合试样的弹性模量;ε为应变。

图10

试验中,岩样①的变形量为Δh1,岩样②的变形量为Δh2,复合试样的总变形量为Δh,则有

若复合试样中,岩样①和岩样②的体积占比分别为v和1-v,则有

而本次试验中岩样①和岩样②体积占比相同,由此可得:

同样也可得:

由图5中各岩石的应变值可知,矽卡岩、砂岩和蛇纹岩的峰值应变分别为0.37、0.61和0.50。蛇纹岩—矽卡岩的理论峰值应变为0.44,试验峰值应变为0.42,误差为4.76%;蛇纹岩—砂岩的理论峰值应变为0.56,试验峰值应变为0.60,误差为6.67%。

由图7中各岩石的弹性模量可知,矽卡岩、砂岩和蛇纹岩的弹性模量分别为33.81,21.41,25.86 GPa;蛇纹岩—砂岩的理论弹性模量为29.30 GPa,试验弹性模量为26.01 GPa;而蛇纹岩—矽卡岩的理论弹性模量为23.43 GPa,试验弹性模量为19.72 GPa。2组复合岩石的弹性模量均呈现为理论值大于试验值的规律。这是因为在理论情况下,复合岩石材料占比相同,均质且各向同性,其变化率稳定,且未考虑接触面胶结,而实际试验中,应力稳定时弱端岩石占比偏小导致理论值偏大,同时,岩石组分的非均质性、层间效应和岩样之间的差异也会对试验结果产生影响。其中,具体的影响因子和对应的影响程度有待进一步研究。

4 结论

(1)在单轴压缩条件下,复合岩石与单一岩石的破坏模式类似,均具有特征明显的压密阶段、弹性阶段、塑性阶段和破坏阶段。复合岩石中岩石强度较低的部分首先发生破坏,初始裂纹的萌生位置和发展模式直接决定着岩样的最终破坏形态。

(2)复合岩石与其所组成的单一岩石之间的抗压强度数值关系为B2=AC。

(3)复合岩石可被视为2个弹簧串联形成的弹性模型,且其抗压强度、弹性模量和峰值应变存在可推导的数值关系。

http://www.goldsci.ac.cn/article/2022/1005-2518/1005-2518-2022-30-5-778.shtml

参考文献

Distinct element numerical analysis of failure process of interlayered rock subjected to uniaxial compression

[J].

Numerical simulation for burst failure of two-body rock structure

[J].

Classification of failure modes and controlling measures for surrounding rock of large-scale caverns with high geostress

[J].

Experimental study on strength and fracture characteristics of hard rock under different stress conditions

[J].

Experimental study on damage evolution law of layered composite rock based on acoustic emission

[J].

The method to identify characteristic stresses of rock in different stages during failure process

[J].

Research on strength and failure mechanism of deep coal-rock combination bodies of different inclined angles

[J].

Experimental and numerical study on the mechanical characteristics of rock-like materials

[J].

Research on roof falling mechanism of deteriorative strata combination supported by bolts

[J].

DEM investigation on tunnel excavation of deeply-situated composite rock mass with different strength ratios

[J].

Strength analysis of rock material under the brittle shear failure mode

[J].

Shaking table test of dynamic responses of a layered complex rock slope under earthquake

[J].

Effects of rock strength on mechanical behavior and acoustic emission characteristics of samples composed of coal and rock

[J].

Review of numerical modeling based on digital image processing for rock mechanics applications

[J].

Mechanical properties of similar material specimens of composite rock masses with different strengths under uniaxial compression

[J].

Study on the effect of inhomogeneous bedding plane on the mechanical properties of uniaxial compression of layered rock mass

[J].

Mechanical properties and failure behavior of rock with different flaw inclinations under coupled static and dynamic loads

[J].

Experimental study on strength and deformation characteristics of layered composite sandstone

[J].

A failure criterion of composite rock

[J].

Mesoscopic model of failure process of interlayered rock compression

[J].

A failure criterion for layered composite rock under true triaxial stress conditions

[J].

Effects of combination mode on mechanical properties and failure characteristics of the coal-rock combinations

[J].

Damage modes and energy characteristics of rock-like materials under dynamic load

[J].

单轴压缩下软硬互层岩石破裂过程的离散元数值分析

[J].

两体岩石结构冲击失稳破坏的数值模拟

[J].

高地应力条件下大型地下洞室群围岩失稳模式分类及调控对策

[J].

不同应力条件下硬岩强度与破裂特性试验研究

[J].

基于声发射的层状复合岩石损伤演化规律实验研究

[J].

岩石变形破坏各阶段强度特征值确定方法

[J].

不同倾角组合煤岩体的强度与破坏机制研究

[J].

类岩石材料力学特性的试验及数值模拟研究

[J].

岩层组合劣化型冒顶机制研究

[J].

深部复合岩体隧道开挖离散元模拟

[J].

岩石材料脆性剪切破坏模式下的强度分析

[J].

层状复合岩体边坡动力特性及地震响应特性的振动台试验研究

[J].

岩石强度对于组合试样力学行为及声发射特性的影响

[J].

基于数字图像处理的岩石数值模拟研究进展

[J].

单轴压缩下不同强度组合复合岩体相似材料试件力学特性研究

[J].

层状岩体单轴压缩力学特性的非均质层面影响效应研究

[J].

层状组合砂岩强度及变形特性试验研究

[J].

复合岩石的破坏准则

[J].

应力作用下软硬互层岩石破裂过程的细观模拟

[J].

真三轴应力条件下层状复合岩石破坏准则

[J].

组合方式对煤岩组合体力学特性和破坏特征影响的试验研究

[J].

动载作用下岩石类材料破坏模式及能量特性

[J].

甘公网安备 62010202000672号

甘公网安备 62010202000672号